Product Description

Product Description

Main Dimensions & Performance Dat

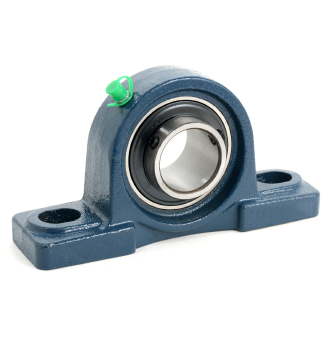

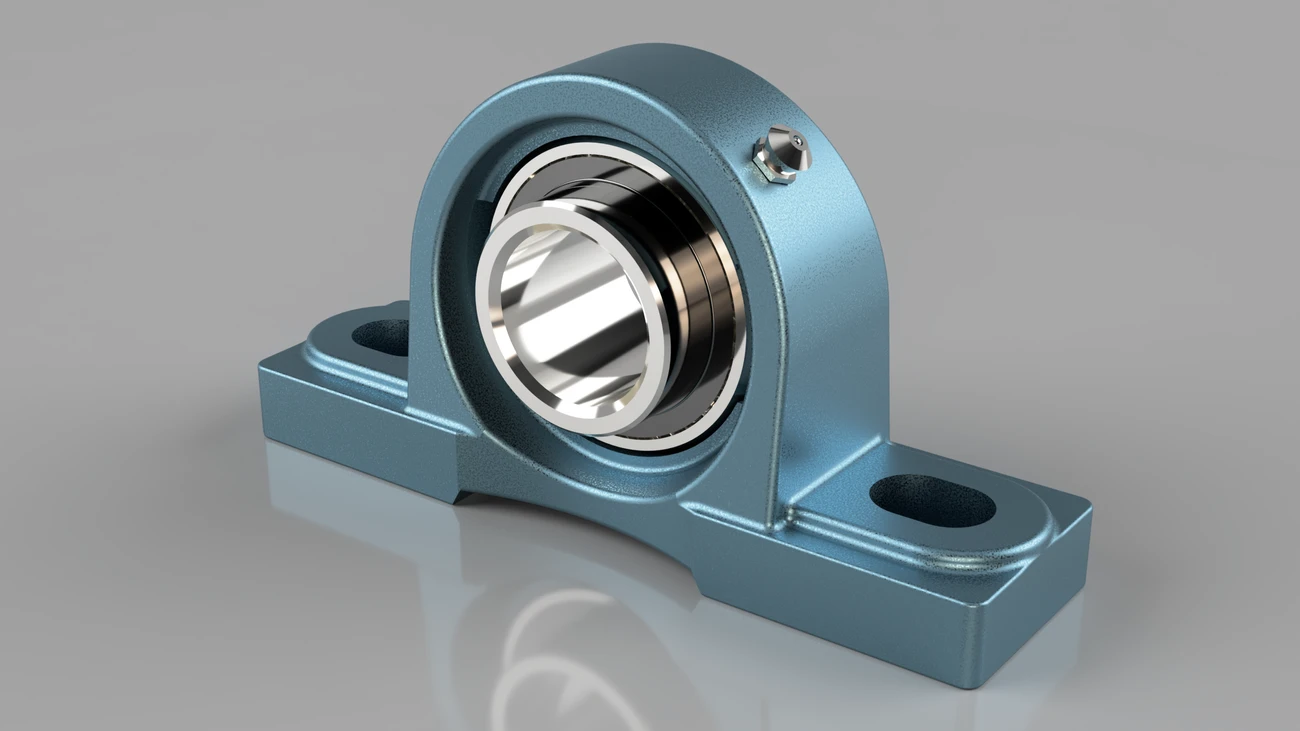

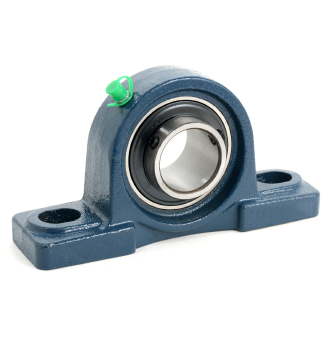

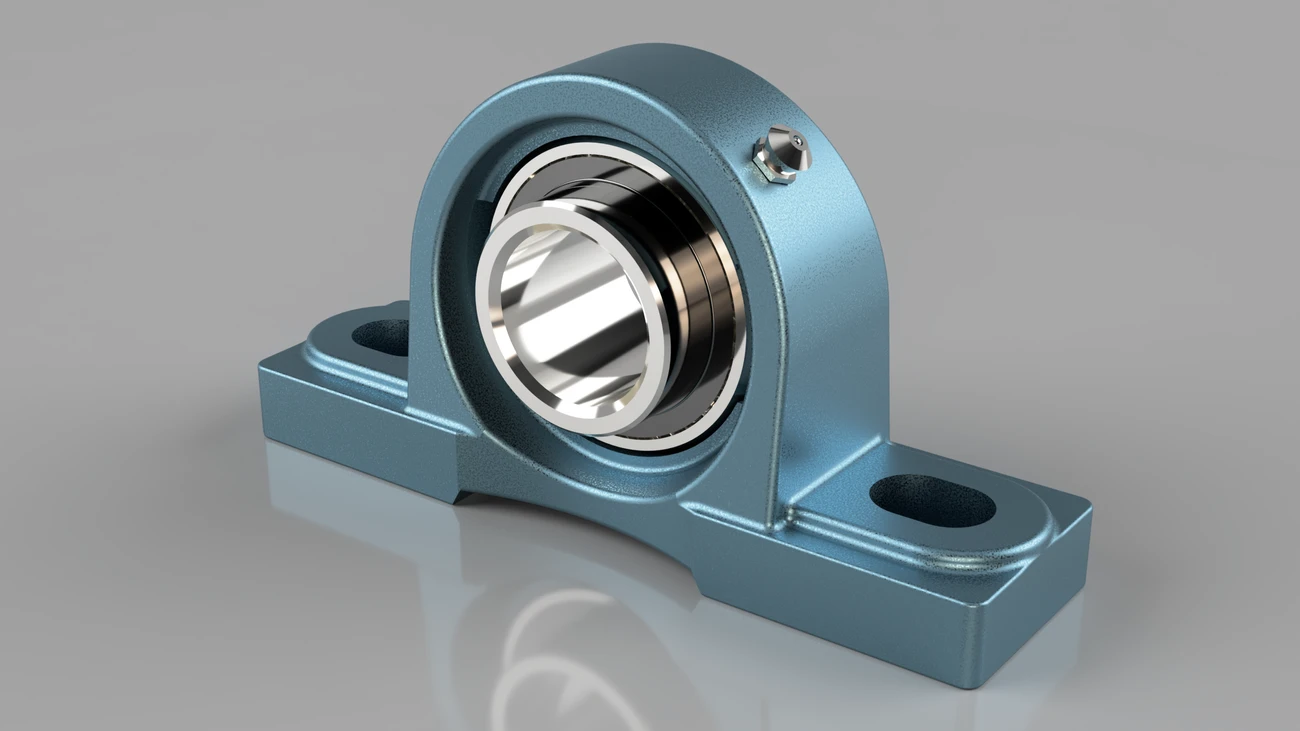

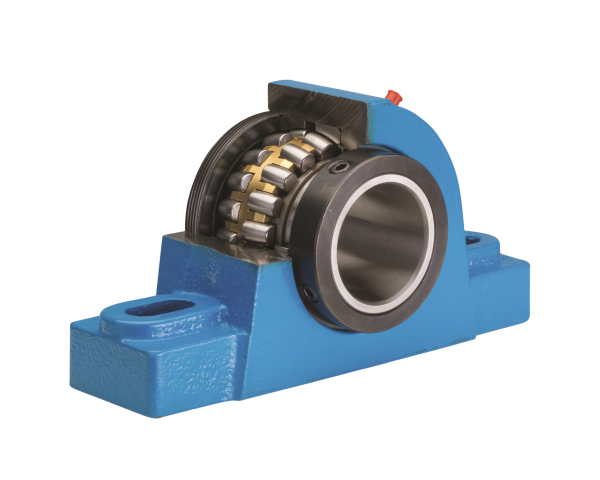

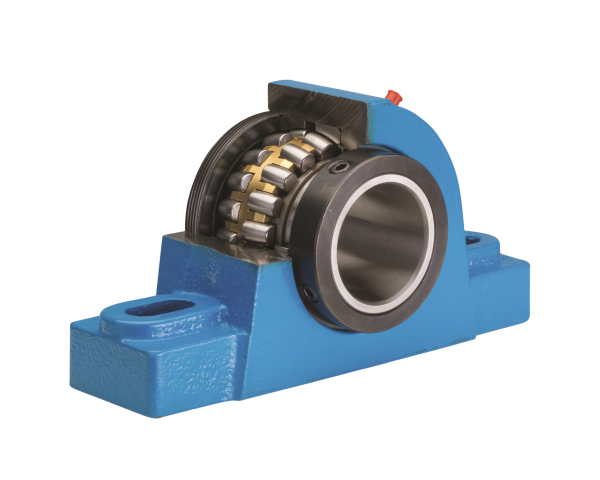

Pillow block bearing unit is a bearing unit that combines a rolling bearing with a bearing housing. Most pillow block bearings are made of spherical outer diameter and are installed with pillow block which have spherical inner holes. They have various structural forms, good versatility and interchangeability.

PILLOW BLOCK BEARINGS

Pillow block bearings, flange bearing units, bearing blocks, and take-up bearings units all consist of a housing with a bearing mounted in it they are available in a variety of materials, mounting configurations and various bearing features each mounted unit, including a mounted uc,sa,sb er series insert bearings.

Uses of Pillow Block Bearing

These units are extremely versatile and can be used in a variety of applications. They range from single bearing shafts to multiple bearing units.

1)Belt drive connecting motor and pump

2)A long shaft connecting the motor and the industrial gearbox

3)Conveyor roller

4)Rolling machine

5)Ventilation system

6)Paper machine

Detailed Photos

Pillow block bearing specifications:

| Unit No | Shaft Dia | Dimensions (mm) | Weight(kg) | |||||||||

| D | B | S | L | J | H | H1 | A | N | N1 | |||

| UCP201 | 12 | 40 | 27.4 | 11.5 | 125 | 96 | 30.2 | 57 | 36 | 13 | 19 | 0.6 |

| UCP202 | 15 | 40 | 27.4 | 11.5 | 125 | 96 | 30.2 | 57 | 36 | 13 | 19 | 0.7 |

| UCP203 | 17 | 40 | 27.4 | 11.5 | 125 | 96 | 30.2 | 57 | 36 | 13 | 19 | 0.7 |

| UCP204 | 20 | 47 | 31 | 12.7 | 127 | 95 | 33.3 | 65 | 38 | 13 | 19 | 0.75 |

| UCP205 | 25 | 52 | 34.1 | 14.3 | 140 | 105 | 36.5 | 71 | 38 | 13 | 19 | 0.8 |

| UCP206 | 30 | 62 | 38.1 | 15.9 | 165 | 121 | 42.9 | 83 | 48 | 17 | 23 | 1.3 |

| UCP207 | 35 | 72 | 42.9 | 17.5 | 167 | 127 | 46.7 | 93 | 48 | 17 | 23 | 1.6 |

| UCP208 | 40 | 80 | 42.9 | 19 | 184 | 137 | 49.2 | 100 | 54 | 17 | 23 | 1.9 |

| UCP209 | 45 | 85 | 49.2 | 19 | 190 | 146 | 54 | 106 | 54 | 17 | 23 | 2.2 |

| UCP210 | 50 | 90 | 51.6 | 19 | 206 | 159 | 57.2 | 114 | 60 | 20 | 26 | 2.6 |

| UCP211 | 55 | 100 | 55.6 | 22.2 | 219 | 171 | 63.5 | 126 | 60 | 20 | 26 | 3.3 |

| UCP212 | 60 | 110 | 65.1 | 25.4 | 241 | 184 | 69.8 | 138 | 70 | 20 | 26 | 4.6 |

| UCP213 | 65 | 120 | 65.1 | 25.4 | 265 | 203 | 76.2 | 151 | 70 | 25 | 31 | 5.9 |

| UCP214 | 70 | 125 | 74.6 | 30.2 | 266 | 210 | 79.4 | 157 | 72 | 25 | 31 | 6.6 |

| UCP215 | 75 | 130 | 77.8 | 33.3 | 275 | 217 | 82.6 | 163 | 74 | 25 | 31 | 7.4 |

| UCP216 | 80 | 140 | 82.6 | 33.3 | 292 | 232 | 88.9 | 175 | 78 | 25 | 31 | 9.0 |

| UCP217 | 85 | 150 | 85.7 | 34.1 | 310 | 247 | 95.2 | 187 | 83 | 25 | 31 | 11 |

| UCP218 | 90 | 160 | 96 | 39.7 | 327 | 262 | 101.6 | 200 | 88 | 27 | 33 | 13 |

| UCP220 | 100 | 180 | 108 | 42 | 380 | 308 | 115 | 225 | 95 | 30 | 38 | 16 |

| UCP305 | 25 | 62 | 38 | 15 | 175 | 132 | 45 | 85 | 45 | 17 | 20 | 1.4 |

| UCP306 | 30 | 72 | 43 | 17 | 180 | 140 | 50 | 95 | 50 | 17 | 20 | 1.8 |

| UCP307 | 35 | 80 | 48 | 19 | 210 | 160 | 56 | 106 | 56 | 17 | 25 | 2.8 |

| UCP308 | 40 | 90 | 52 | 19 | 220 | 170 | 60 | 116 | 60 | 17 | 27 | 3.0 |

| UCP309 | 45 | 100 | 57 | 22 | 245 | 190 | 67 | 129 | 67 | 20 | 30 | 4.1 |

| UCP310 | 50 | 110 | 61 | 22 | 275 | 212 | 75 | 143 | 75 | 20 | 35 | 5.8 |

| UCP311 | 55 | 120 | 66 | 25 | 310 | 236 | 80 | 154 | 80 | 20 | 38 | 7.4 |

| UCP312 | 60 | 130 | 71 | 26 | 330 | 250 | 85 | 165 | 85 | 25 | 38 | 9.4 |

| UCP313 | 65 | 140 | 75 | 30 | 340 | 260 | 90 | 176 | 90 | 25 | 38 | 10.0 |

| UCP314 | 70 | 150 | 78 | 33 | 360 | 280 | 95 | 187 | 90 | 27 | 40 | 12.0 |

| UCP315 | 75 | 160 | 82 | 33 | 380 | 290 | 100 | 198 | 100 | 27 | 40 | 14.0 |

| UCP316 | 80 | 170 | 86 | 34 | 400 | 300 | 106 | 210 | 110 | 27 | 40 | 18.0 |

| UCP317 | 85 | 180 | 96 | 40 | 420 | 320 | 112 | 220 | 110 | 33 | 45 | 20.0 |

| UCP318 | 90 | 190 | 96 | 40 | 430 | 330 | 118 | 235 | 110 | 33 | 45 | 24.0 |

| UCP319 | 95 | 200 | 103 | 41 | 470 | 360 | 125 | 250 | 120 | 36 | 50 | 29.0 |

| UCP320 | 100 | 215 | 108 | 42 | 490 | 380 | 140 | 275 | 120 | 36 | 50 | 35.0 |

| UCP321 | 105 | 225 | 112 | 44 | 490 | 380 | 140 | 280 | 120 | 36 | 50 | 35.0 |

| UCP322 | 110 | 2240 | 117 | 46 | 520 | 400 | 150 | 300 | 140 | 40 | 55 | 45.0 |

| UCP324 | 120 | 260 | 126 | 51 | 570 | 450 | 160 | 320 | 140 | 40 | 55 | 55.0 |

| UCP326 | 130 | 280 | 135 | 54 | 600 | 480 | 180 | 355 | 140 | 40 | 55 | 72.0 |

| UCP328 | 140 | 300 | 145 | 59 | 620 | 500 | 200 | 390 | 140 | 40 | 55 | 89.0 |

Packaging & Shipping

Packing:

Please contact us for more pictures of different packing.

|

Universal Packing |

Without any logo on bearings or packing. |

|

JDZ Packing |

With our brand JDZ on bearings and packing. |

|

Customized Packing |

Depends on buyer’s requirements. |

|

Original Brand Packing |

Bearing and packing are both original. Please contact us for pictures. |

QUALITY ASSURANCE

100% Quality inspection to ensure the bearings are with good quality before shipping.

Company Profile

ZheJiang CZPT Precision Bearing Co.,Ltd. was founded by ZheJiang Defa Bearing Co.,Ltd, factory is located in ZheJiang province, China.

We are a bearing manufacturer integrating the research, development and sales of bearings, with a floor area of 18,000 square meters and a plant area of 8,800 square meters. Equipped with modern production equipment and advanced detection instruments.

We can provide all types bearings and OEM service according to customers’ requirements.

Our products are widely used in the automobile, agricultural, textile production, mining, printing and packing industries, in addition to various applications at airports, in air-conditioning systems, conveying devices, ships ad so on. Our products are being exported to more than 50 countries and regions overseas including Singapore, Thailand, Iran, Turkey, Poland, Italy, England, France, Russia, Germany, the United States, Australia, Argentina, Brazil as well as other countries and regions all over the world.

We are a trusted and reliable bearing supplier, choose us to be your good partner!

Quality Inspection.

Our Advantages:

1. Professional production team with advanced production equipment and testing instruments.

2. Many years of export experience can provide customers with better service and problem-solving capabilities.

3. Customers all over the world enable us to better understand the market and provide customers with suitable bearings.

4. Sincerity, cooperation, mutual and provide good quality bearings for clients are the development idea of our company

5. Quick delivery, shipping goods on time. Save more time and cost for all customers.

FAQ

1. Q: Are you trading company or manufacturer ?

A: We have our own factory , our type is factory + trade.

2. Q: Could you accept OEM and customize?

A: Yes, we can customize products according to your sample or drawing.

3. Q: How long is your delivery time?

A: If stock, within 7 days to ship or based on your order quantity.

4. Q: Could you supply sample for free?

A: Yes, we can offer the sample for free,do you mind to buy a “ticket” for her?

More details, please contact with us. Thanks for your time!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What challenges are associated with lubrication distribution in pillow block bearings, and how are they addressed?

Lubrication distribution in pillow block bearings can pose certain challenges, but these challenges can be effectively addressed through various methods and techniques. Here are the key challenges associated with lubrication distribution in pillow block bearings and their corresponding solutions:

- Inadequate Lubricant Supply:

- Lubricant Contamination:

- Uneven Lubrication Distribution:

- Over-Lubrication:

- Lubricant Degradation:

- Automatic Lubrication Systems:

One common challenge is ensuring an adequate and consistent supply of lubricant to the bearing. Inadequate lubrication can lead to increased friction, heat generation, and premature wear. To address this challenge, proper lubrication procedures should be followed, including using the correct type and quantity of lubricant recommended by the bearing manufacturer. Regular lubrication inspections and monitoring can help ensure that the bearing receives sufficient lubricant to maintain optimal performance.

Contamination of the lubricant can occur due to various factors, such as the ingress of dirt, dust, or moisture into the bearing housing. Contaminated lubricant can hinder proper lubrication distribution and compromise the bearing’s performance. To address this challenge, effective sealing mechanisms, such as rubber seals or labyrinth seals, are incorporated into pillow block bearings to prevent the entry of contaminants. Regular inspection and cleaning of the bearing housing and lubrication system can also help maintain a clean lubricant supply.

Uneven distribution of lubricant within the bearing can lead to localized areas of high friction and increased wear. This can occur due to factors such as improper lubrication techniques, misalignment, or the presence of obstructions within the bearing housing. To address this challenge, it is crucial to follow the manufacturer’s guidelines for lubrication methods and intervals. Proper alignment of the bearing and shafts, along with regular inspection and maintenance, can help ensure even lubricant distribution and prevent premature wear.

Over-lubrication can be as detrimental as inadequate lubrication. Excessive lubricant can result in increased drag, higher operating temperatures, and potential leakage. It can also lead to the accumulation of contaminants within the bearing housing. To overcome this challenge, it is essential to adhere to the recommended lubrication quantities specified by the bearing manufacturer. Monitoring techniques, such as visual inspection or the use of condition monitoring tools, can help identify signs of over-lubrication and allow for adjustments to be made accordingly.

Lubricants can degrade over time due to factors such as oxidation, contamination, or high operating temperatures. Degraded lubricants lose their effectiveness, leading to inadequate lubrication and increased friction. To address this challenge, regular lubricant analysis and monitoring can help determine the lubricant’s condition and identify the need for replenishment or replacement. Lubricant selection should also consider the operating conditions and temperature ranges to ensure optimal performance and longevity.

Pillow block bearings in certain applications benefit from the use of automatic lubrication systems. These systems provide a controlled and consistent supply of lubricant to the bearing, eliminating the challenges associated with manual lubrication. Automatic lubrication systems can be designed to deliver precise amounts of lubricant at regular intervals, ensuring optimal lubrication distribution. They can also incorporate monitoring features to detect abnormalities or malfunctions in the lubrication system and allow for timely corrective actions.

In summary, challenges associated with lubrication distribution in pillow block bearings include inadequate lubricant supply, lubricant contamination, uneven distribution, over-lubrication, lubricant degradation, and the need for precise and consistent lubrication. These challenges can be effectively addressed through proper lubrication procedures, sealing mechanisms, regular inspection and maintenance, adherence to manufacturer guidelines, monitoring techniques, lubricant analysis, and the use of automatic lubrication systems where applicable. By addressing these challenges, optimal lubrication distribution can be achieved, leading to improved performance, reduced wear, and extended bearing life.

Can you provide examples of scenarios where easy mounting and dismounting are crucial with pillow block bearings?

Easy mounting and dismounting of pillow block bearings are crucial in various scenarios where maintenance, repair, or replacement of bearings is required. Here are some examples of situations where easy mounting and dismounting are particularly important:

- Field Maintenance:

- Conveyor Systems:

- High-Speed Machinery:

- Service and Repair Workshops:

- Equipment with Limited Access:

In industries such as agriculture, construction, and mining, equipment often operates in remote or challenging locations. In these scenarios, quick and easy mounting and dismounting of pillow block bearings are essential for efficient field maintenance. Bearings may need to be replaced or serviced on-site to minimize downtime and keep the equipment operational. Easy access to the bearings and straightforward mounting and dismounting procedures enable maintenance personnel to perform these tasks effectively and swiftly.

Conveyor systems are widely used in industries such as manufacturing, warehousing, and logistics. These systems consist of numerous pillow block bearings that support the conveyor rollers or pulleys. In situations where a bearing fails or requires maintenance, easy mounting and dismounting are crucial to minimize disruption to the production or material handling process. Efficient replacement of the bearing allows the conveyor system to resume operation quickly and ensures smooth material flow.

In applications involving high-speed machinery, such as paper mills, printing presses, or textile machinery, easy mounting and dismounting of pillow block bearings are important. These machines often operate at high rotational speeds, and any downtime for bearing replacement or maintenance can have a significant impact on productivity. Quick and hassle-free mounting and dismounting procedures allow maintenance teams to swiftly address bearing issues and restore the machinery to its optimal performance.

Service and repair workshops that handle a wide range of equipment from different industries benefit from easy mounting and dismounting of pillow block bearings. These workshops often deal with various machinery types and sizes, and having a streamlined process for bearing replacement or maintenance is crucial to ensure efficient service delivery. Easy mounting and dismounting procedures simplify the workflow, reduce labor time, and enhance overall operational efficiency.

Some equipment may have limited access to the bearings due to space constraints or design considerations. Examples include compact machinery, enclosed systems, or installations with complex configurations. In such cases, easy mounting and dismounting of pillow block bearings become even more critical. Simplified procedures and accessible mounting points facilitate the replacement or maintenance of bearings in these challenging environments.

In summary, easy mounting and dismounting of pillow block bearings are crucial in scenarios where efficient maintenance, repair, or replacement of bearings is required. This includes field maintenance, conveyor systems, high-speed machinery, service and repair workshops, and equipment with limited access. By enabling quick and hassle-free procedures, easy mounting and dismounting of pillow block bearings contribute to minimizing downtime, optimizing equipment performance, and ensuring smooth operations in various industries and applications.

Can you explain the design principles of pillow block bearings and their functions?

Pillow block bearings, also known as plummer block bearings, are designed based on certain principles to ensure their functionality and performance. Understanding the design principles can provide insights into how these bearings operate and fulfill their intended functions. Here’s a detailed explanation of the design principles of pillow block bearings and their functions:

- Housing Design:

- Bearing Insert:

- Self-Aligning Capability:

- Load Support:

- Lubrication:

- Environmental Protection:

The housing of a pillow block bearing is typically made of cast iron or pressed steel and has a split design. The split housing allows for easy installation and maintenance by providing access to the bearing insert without the need to disassemble the entire system. The housing also includes mounting holes or slots for attaching the bearing to a support structure, such as a machine frame or conveyor system.

The bearing insert is a key component of a pillow block bearing. It is pre-mounted inside the housing and provides the rotating element to support shafts or other moving parts. The design of the bearing insert depends on the specific application requirements. Common types of bearing inserts used in pillow block bearings include deep groove ball bearings, spherical roller bearings, and cylindrical roller bearings. The selection of the appropriate bearing insert depends on factors such as load capacity, speed, and environmental conditions.

Pillow block bearings are designed with a certain degree of self-aligning capability. This means that they can accommodate slight misalignments or shaft deflections without causing undue stress on the bearing or affecting its performance. The self-aligning capability is achieved through the design of the bearing insert and the housing. It helps to ensure smooth operation, reduce wear, and prolong the bearing’s service life.

Pillow block bearings are primarily designed to support rotating shafts and transmit loads between the shaft and the housing. They are capable of handling both radial and axial loads, depending on the type of bearing insert used. The design of the bearing insert and the housing is optimized to provide optimal load-carrying capacity and distribute the loads evenly, minimizing stress concentrations and maximizing the bearing’s performance.

Lubrication is crucial for the proper functioning and longevity of pillow block bearings. The housing design often includes provisions for grease or oil lubrication. Lubrication helps to reduce friction, dissipate heat, prevent wear, and protect against corrosion. Proper lubrication ensures smooth operation, minimizes power losses, and extends the service life of the bearing.

Pillow block bearings are designed to provide a degree of environmental protection to the bearing insert. The housing acts as a shield, preventing contaminants such as dust, dirt, and moisture from entering the bearing and causing premature failure. The housing design may include features such as seals or shields to further enhance the protection against contaminants. This design principle helps to maintain the integrity of the lubrication and ensure reliable operation in various working environments.

In summary, pillow block bearings are designed based on certain principles to ensure their functionality and performance. The housing design allows for easy installation and maintenance, while the bearing insert provides the rotating element to support shafts and transmit loads. The self-aligning capability accommodates misalignments, and the optimized design of the bearing insert and housing ensures proper load support. Lubrication and environmental protection features contribute to smooth operation and extended service life. Understanding these design principles helps in selecting and utilizing pillow block bearings effectively in various industrial applications.

editor by CX 2024-05-16

China supplier Ucfx07-23 Ucfx07 Ucfx08-24 Stainless Steel Food Beverage Shops Stainless Steel Pillow Block Ball Bearing Housing Bearing bearing bronze

Product Description

Product Description

Pillow block bearing

Bearings used with suitable standard housings are an economical, interchangeable method of bearing arrangement and simplify maintenance.

Based on the experience accumulated in various industrial fields, new designs and practical housings are continuously developed to meet the requirements of different applications.

Standard housings include:

Partial housing

Integral bearing housing

Flanged housing

Product Parameters

Product Specification

1. Needle roller bearing without inner ring

UCPG200

| BearingUint No | Shaft Dia d | Dimensinons(mm) | Bolt Used | Bearing No | Housing No | Housing Wt (Kg) |

||||||||||

| (in) | (mm) | h | a | e | b | t | r | g | W | Bi | n | (mm) | ||||

| UCPG201-8 UCPG202-9 UCPG202-10 UCPG203-11 UCPG201 UCPG202 UCPG203 |

1/2 9/16 518 11/16 |

12 15 17 |

30.2 | 55 | 38 | 30 | M6 | 12 | 14 | 57 | 26 | 10 | M6X1 | UCW201-8 UCW202-9 UCW202-10 UCW203-11 UCW201 UCW202 UCW203 |

PG203 | 0.3 |

| UCPG201-8 | 1/2 | 33.3 | 70 | 49 | 38 | M8 | 15 | 14 | 64 | 31 | 12.7 | M8x1.25 | UC201-8 | PG204 | 0.5 | |

| UCPG202-9 | 9/16 | UC202-9 | ||||||||||||||

| UCPG202-10 | 5/8 11/16 |

UC202-10 | ||||||||||||||

| UCPG203-11 | UC203-11 | |||||||||||||||

| CPG204-12 | 3/4 | UC204-12 | ||||||||||||||

| UCPG201 | 12 | UC201 | ||||||||||||||

| UCPG202 | 15 | UC202 | ||||||||||||||

| UCPG203 | 17 | UC203 | ||||||||||||||

| UCPG204 | 20 | UC204 | ||||||||||||||

| UCPG205-13 | 13/16 | 25 | 36.5 | 75 | 50 | 38 | M10 | 15 | 15 | 70 | 34.1 | 14.3 | M10x1.5 | JC205-13 | PG205 | 0.5 |

| UCPG205-14 | 7/8 | UC205-14 | ||||||||||||||

| UCPG205-15 | 15/16 | JC205-15 | ||||||||||||||

| UCPG205-16 | 1 | UC205-16 | ||||||||||||||

| UCPG205 | UC205 | |||||||||||||||

| UCPG206-17 | 1-1/16 | 30 | 42.9 | 85 | 60 | 48 | M10 | 18 | 17 | 83 | 38.1 | 15.9 | M10x1.5 | UC206-17 | PG206 | 0.75 |

| UCPG206-18 | 1-1/8 | UC206-18 | ||||||||||||||

| JCPG206-19 | 1-3/16 | UC206-19 | ||||||||||||||

| UCPG206-20 | 1-1/4 | UC206-20 | ||||||||||||||

| UCPG206 | UC206 | |||||||||||||||

| UCPG207-20 | 1-1/4 | 35 | 47.6 | 100 | 68 | 48 | M12 | 18 | 17 | 93 | 42.9 | 175 | M12x1.75 | UC207-20 | PG207 | 1.3 |

| UCPG207-21 | 1-5/16 | UC207-21 | ||||||||||||||

| UCPG207-22 | 1-3/8 | UC207-22 | ||||||||||||||

| UCPG207-23 | 1-7/16 | UC207-23 | ||||||||||||||

| UCPG207 | UC207 | |||||||||||||||

| UCPG208-24 | 1-1/2 | 40 | 49.2 | 110 | 78 | 54 | M12 | 18 | 20 | 98 | 49.2 | 19.0 | M12x1.75 | UC208-24 | PG208 | 1.2 |

| UCPG208-25 | 1-9/16 | UC208-25 | ||||||||||||||

| UCPG208 | UC208 | |||||||||||||||

| UCPG209-26 | 1-5/8 | 45 | 53.9 | 120 | 85 | 54 | M12 | 22 | 20 | 106 | 49.2 | 19.0 | M12x1.75 | UC209-26 | PG209 | 1.6 |

| UCPG209-27 | 1-11/16 | UC209-27 | ||||||||||||||

| UCPG209-28 | 1-3/4 | UC209-28 | ||||||||||||||

| UCPG209 | UC209 | |||||||||||||||

| UCPG210-29 | 1-13/16 | 50 | 57.2 | 135 | 95 | 60 | M16 | 25 | 21 | 114 | 51.6 | 19.0 | M16x2 | UC210-29 | PG210 | 2.2 |

| UCPG210-30 | 1-7/8 | UC210-30 | ||||||||||||||

| UCPG210-31 | 1-15/16 | UC210-31 | ||||||||||||||

| UCPG210-32 | 2 | UC210-32 | ||||||||||||||

| UCPG210 | UC210 | |||||||||||||||

| UCPG211-32 UCPG211-33 UCPG211-34 UCPG211-35 UCPG211 |

2 2-1/16 2-1/8 2-3/16 |

55 | 63.5 | 140 | 100 | 60 | M16 | 25 | 25 | 126 | 55.6 | 22.2 | M16x2 | UC211-32 UC211-33 UC211-34 UC211-35 UC211 |

PG211 | 2.7 |

| UCPG212-36 UCPG212-37 UCPG212-38 UCPG212-39 UCPG212 |

2-1/4 2-5/16 2-3/8 2-7/16 |

60 | 69.8 | 150 | 105 | 70 | M16 | 25 | 25 | 138 | 65.1 | 25.4 | M16x2 | JC212-36 UC212-37 JC212-38 UC212-39 UC212 |

PG212 | 3.15 |

UCPH200

| BearingUint No | Shaft Dia d | Dimensinons(mm) | Bolt Used | Bearing No | Housing No | Housing Wt(kg |

|||||||||||

| in) | (mm) | h | a | e | b | S2 | S1 | g | W | Bi | n | (mm) | (in) | ||||

| UCPH201-8 | 1/2 | 70 | 127 | 95 | 40 | 19 | 13 | 15 | 101 | 31 | 12.7 | M10 | 3/8 | UC201-8 | PH204 | 0.75 | |

| UCPH202-9 | 9/16 | UC202-9 | |||||||||||||||

| UCPH202-10 | 5/8 | UC202-10 | |||||||||||||||

| UCPH203-11 | 11/16 | UC203-11 | |||||||||||||||

| UCPH204-12 | 3/4 | UC204-12 | |||||||||||||||

| UCPH201 | 12 | UC201 | |||||||||||||||

| UCPH202 | 15 | UC202 | |||||||||||||||

| UCPH203 | 17 | UC203 | |||||||||||||||

| UCPH204 | 20 | UC204 | |||||||||||||||

| UCPH205-13 | 13/16 | 25 | 80 | 140 | 105 | 50 | 19 | 13 | 16 | 114 | 34.1 | 14.3 | M10 | 3/8 | UC205-13 | PH205 | 1.0 |

| UCPH205-14 | 7/8 | UC205-14 | |||||||||||||||

| UCPH205-15 | 15/16 | UC205-15 | |||||||||||||||

| UCPH205-16 | UC205-16 | ||||||||||||||||

| UCPH205 | UC205 | ||||||||||||||||

| UCPH206-17 | 1-1/16 | 30 | 90 | 165 | 121 | 50 | 21 | 17 | 18 | 130 | 38.1 | 15.9 | M14 | 1/2 | UC206-17 | PH206 | 1.42 |

| UCPH206-18 | 1-1/8 | UC206-18 | |||||||||||||||

| UCPH206-19 | 1-3/16 | UC206-19 | |||||||||||||||

| UCPH206-20 | 1-1/4 | UC206-20 | |||||||||||||||

| UCPH206 | UC206 | ||||||||||||||||

| UCPH207-20 | 1-1/4 | 35 | 95 | 167 | 127 | 60 | 21 | 17 | 19 | 140 | 42.9 | 17.5 | M14 | 1/2 | UC207-20 | PH207 | 1.55 |

| UCPH207-21 | 1-5/16 | UC207-21 | |||||||||||||||

| UCPH207-22 | 1-3/8 | UC207-22 | |||||||||||||||

| UCPH207-23 | 1-7/16 | UC207-23 | |||||||||||||||

| UCPH207 | UC207 | ||||||||||||||||

| UCPH208-24 | 1-1/2 | 40 | 100 | 184 | 137 | 70 | 25 | 17 | 19 | 149 | 49.2 | 19.0 | M14 | 1/2 | UC208-24 | PH208 | 2.15 |

| UCPH208-25 | 1-9/16 | UC208-25 | |||||||||||||||

| UCPH208 | UC208 | ||||||||||||||||

| UCPH209-26 | 1-5/8 | 45 | 105 | 190 | 146 | 70 | 25 | 17 | 20 | 157 | 49.2 | 19.0 | M14 | 1/2 | UC209-26 | PH209 | 2.31 |

| UCPH209-27 | 1-11/16 | UC209-27 | |||||||||||||||

| UCPH209-28 | 1-3/4 | UC209-28 | |||||||||||||||

| UCPH209 | UC209 | ||||||||||||||||

| UCPH210-29 | 1-13/16 | 50 | 110 | 206 | 159 | 70 | 25 | 20 | 22 | 165 | 51.6 | 19.0 | M16 | 5/8 | UC210-29 | PH210 | 2.80 |

| UCPH210-30 | 1-7/8 | UC210-30 | |||||||||||||||

| UCPH210-31 | 1-15/16 | UC210-31 | |||||||||||||||

| UCPH210-32 | 2 | UC210-32 | |||||||||||||||

| UCPH210 | UC210 | ||||||||||||||||

| UCPH211-32 | 2 | 55 | 120 | 219 | 171 | 75 | 22 | 19 | 22 | 181 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 | PH211 | 4.4 |

| UCPH211-33 | 2-1/16 | UC211-33 | |||||||||||||||

| UCPH211-34 | 2-1/8 | UC211-34 | |||||||||||||||

| UCPH211-35 | 2-3/16 | UC211-35 | |||||||||||||||

| UCPH211 | UC211 | ||||||||||||||||

| UCPH212-36 | 2-1/4 | 60 | 130 | 235 | 184 | 85 | 23 | 19 | 25 | 197 | 65.1 | 25.4 | M16 | 5/8 | UC212-36 | PH212 | 4.8 |

| UCPH212-37 | 2-5/16 | UC212-37 | |||||||||||||||

| UCPH212-38 | 2-3/8 | UC212-38 | |||||||||||||||

| UCPH212-39 | 2-7/16 | UC212-39 | |||||||||||||||

| UCPH212 | UC212 | ||||||||||||||||

| UCPH213-40 | 2-1/2 | 65 | 140 | 262 | 203 | 95 | 28 | 23 | 27 | 212 | 65.1 | 25.4 | M20 | 3/4 | UC213-40 | PH213 | 5.6 |

| UCPH213-41 | 2-9/16 | UC213-41 | |||||||||||||||

| UCPH213 | UC213 | ||||||||||||||||

| UCPH214-42 | 2-5/8 | 70 | 150 | 268 | 210 | 105 | 28 | 23 | 28 | 225 | 74.6 | 30.2 | M20 | 3/4 | UC214-42 | PH214 | 6.2 |

| UCPH214-43 | 2-11/16 | UC214-43 | |||||||||||||||

| UCPH214-44 | 2-3/4 | UC214-44 | |||||||||||||||

| UCPH214 | UC214 | ||||||||||||||||

| UCPH215-45 | 2-13/16 | 75 | 160 | 275 | 217 | 115 | 28 | 23 | 29 | 238 | 77.8 | 33.3 | M20 | 3/4 | UC215-45 | PH215 | 7.4 |

| UCPH215-46 | 2-7/8 | UC215-46 | |||||||||||||||

| UCPH215-47 | 2-15/16 | UC215-47 | |||||||||||||||

| UCPH215-48 | 3 | UC215-48 | |||||||||||||||

| UCPH215 | UC215 | ||||||||||||||||

| UCPH216-50 | 3-1/8 | 80 | 170 | 290 | 232 | 125 | 28 | 23 | 30 | 253 | 82.6 | 33.3 | M20 | 3/4 | UC216-50 | PH216 | 8.0 |

| UCPH216 | UC216 | ||||||||||||||||

UCF200

| Bearing Uint No. | Shaft | Dia d | Dimensinons(mm) | Bolt | Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||

| (in) | (mm) | a | e | 9 | s | t | z1 | z | Bi | n | (mm) | (in) | |||||||

| UCF201-8 UCF202-9 UCF202-10 UCF203-11 UCF201 UCF202 UCF203 |

1/2 9/16 5/8 H1/16 |

12 15 17 |

76 | 54 | 15 | 11 | 25.5 | 11.5 | 31 | 26 | 10 | M10 | 3/8 | UCW201-8 UCW202-9 UCW202-10 UCW203-11 UCW201 UCW202 UCW203 |

F203 | 0.5 | |||

| UCF201-8 | /2 | 86 | 64 | 15 | 12 | 25.5 | 12 | 2 | 40.5 | 33.3 | 31 | 12.7 | M10 | 3/8 | UC201-8 UC202-9 UC202-10 UC203-11 UC204-12 UC201 UC202 UC203 |

F204 | 0.6 | ||

| UCF202-9 UCF202-10 UCF203-11 UCF204-12 |

9/16 | ||||||||||||||||||

| 5/8 1/18 34 |

|||||||||||||||||||

| UCF201 | 12 | ||||||||||||||||||

| UCF202 | 15 | ||||||||||||||||||

| UCF203 | 17 | ||||||||||||||||||

| UCF204 | 20 | UC204 | |||||||||||||||||

| UCF205-13 | 13/16 | 25 | 95 | 70 | 16 | 14 | 27 | 12 | 2 | 44.5 | 35.8 | 34.1 | 14.3 | M10 | 3/8 | UC205-13 | F205 | 0.86 | |

| UCF205-14 | 7/8 | UC205-14 UC205-15 UC205-16 UC205 |

|||||||||||||||||

| UCF205-15 | 5/16 | ||||||||||||||||||

| JCF205-16 | 1 | ||||||||||||||||||

| UCF205 | |||||||||||||||||||

| UCF206-17 | -/16 | 30 | 108 | 83 | 18 | 14 | 31 | 12 | 2 | 49 | 40.2 | 38.1 | 15.9 | M10 | 3/8 | UC206-17 UC206-1E UC206-19 |

F206 | 1.1 | |

| UCF206-18 | -1/8 | ||||||||||||||||||

| UCF206-19 | -3/16 | ||||||||||||||||||

| UCF206-20 | 1-1/4 | UC206-20 | |||||||||||||||||

| UCF206 | UC206 | ||||||||||||||||||

| JCF207-20 | 1-1/4 | 35 | 117 | 92 | 19 | 16 | 34 | 14 | 3 | 55 | 44. | 42.9 | 17.5 | M12 | 7/16 | UC207-20 | F207 | 1.6 | |

| UCF207-21 | 1-5/16 | UC207-21 | |||||||||||||||||

| UCF207-22 | 1-3/8 | UC207-22 | |||||||||||||||||

| UCF207-23 | 1-7/16 | UC207-23 | |||||||||||||||||

| JCF207 | UC207 | ||||||||||||||||||

| F208-24 | 1-1/2 | 40 | 130 | 102 | 21 | 16 | 38 | 16 | 3 | 62 | 51.2 | 49.2 | 19 | M14 | 1/2 | UC208-24 | F208 | 1.9 | |

| UCF208-25 | 1-9/16 | UC208-25 UC205 |

|||||||||||||||||

| UCF208 | |||||||||||||||||||

| UCF209-26 | -518 | 45 | 137 | 105 | 22 | 18 | 38 | 16 | 3 | 63 | 52.2 | 49.2 | 19 | M14 | 1/2 | UC209-26 UC209 28 |

F209 | 2.4 | |

| CF209-27 | 1-11/16 | ||||||||||||||||||

| UCF209-28 | -3/4 | ||||||||||||||||||

| UCF209 | UC209 | ||||||||||||||||||

| UCF210-29 | 1-13/16 | 50 | 143 | 111 | 22 | 18 | 40 | 16 | 3 | 66.5 | 54.6 | 51.6 | 19 | M14 | 1/2 | UC210-29 | F210 | 2.6 | |

| UCF210-30 | 1-7/8 | UC210-30 | |||||||||||||||||

| UCF210-31 | 1-15/16 | UC210-31 | |||||||||||||||||

| UCF210-32 | 2 | UC210-32 | |||||||||||||||||

| UCF210 | UC210 | ||||||||||||||||||

| UCF211-32 | 2 | 55 | 162 | 130 | 25 | 20 | 43 | 19 | 4 | 71 | 58.4 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 | F211 | 3.5 | |

| JCF211-33 | 2./16 | UC211-38 | |||||||||||||||||

| UCF211-34 | 2-/8 | UC211-34 UC211-35 |

|||||||||||||||||

| UCF211-35 | 2-3/16 | ||||||||||||||||||

| UCF211 | UC211 | ||||||||||||||||||

| UCF212.36 | 2-1/4 | 60 | 175 | 143 | 29 | 20 | 48 | 19 | 4 | 80 | 68.7 | 65.1 | 25.4 | M16 | 5/8 | UC212-36 | F212 | 4.2 | |

| UCF212-37 | 2-5/16 | UC212-37 | |||||||||||||||||

| UCF212-38 | 2-3/8 | UC212-38 | |||||||||||||||||

| JCF212-39 | 2-7/16 | UC212-39 | |||||||||||||||||

| UCF212 | UC212 | ||||||||||||||||||

| UCF213-40 | 2-1/2 | 65 | 187 | 149 | 30 | 20 | 50 | 19 | 4 | 83.5 | 69.7 | 65.1 | 25.4 | M16 | 5/8 | UC213-40 | F213 | 5.3 | |

| UCF213-41 | 2-9/16 | UC213-41 | |||||||||||||||||

| UCF213 | UC213 | ||||||||||||||||||

| UCF214-42 | 2-518 | 70 | 193 | 152 | 31 | 24 | 54 | 19 | 75.4 | 74.6 | 30.2 | M16 | 5/8 | UC214-42 | F214 | 5.5 | |||

| UCF214-43 | 2-11/16 | UC214-43 | |||||||||||||||||

| UCF214-44 | 2-3/4 | UC214-44 | |||||||||||||||||

| JCF214 | UC214 | ||||||||||||||||||

| UCF215-45 | 2-13/16 | 75 | 200 | 159 | 34 | 24 | 56 | 19 | 78.5 | 77.8 | 33.3 | M16 | 5/8 | UC215-45 | F215 | 6.2 | |||

| UCF215-46 | 2-7/8 | UC215-46 | |||||||||||||||||

| UCF215-47 | 2-15/16 | UC215-47 | |||||||||||||||||

| UCF215-48 | 3 | UC215-48 | |||||||||||||||||

| UCF215 | UC215 | ||||||||||||||||||

| UCF216-50 | 3-1/8 | 80 | 208 | 165 | 34 | 24 | 58 | 23 | 83.3 | 82.6 | 33.3 | M20 | 3/4 | UC216.50 | F216 | 7.7 | |||

| UCF216 | UC216 | ||||||||||||||||||

| UCF217-52 | 3-1/4 | 85 | 220 | 175 | 36 | 26 | 63 | 23 | 87.6 | 85.7 | 34.1 | M20 | 3/4 | UC217-52 | F217 | 9 | |||

| UCF217 | UC217 | ||||||||||||||||||

| UCF218-56 | 3-1/2 | 90 | 235 | 187 | 40 | 26 | 68 | 23 | 96.3 | 96.0 | 39.7 | M20 | 3/4 | UC218-56 UC218 |

F218 | 11.3 | |||

| UCF218 | |||||||||||||||||||

UCFX00

| Bearing Unit NO |

Shaft Dia d |

Dimensions(mm) | Bolt Used | Beafing No |

Housing No |

Housing Wt (kg) |

||||||||||

| (in) | (mm) | a | e | i | g | S | z | Bi | n | (in) | (mm) | |||||

| UCFX05-16 UCFX05 |

25 | 108 | 83 | 18 | 13 | 30 | 12 | 40.2 | 38.1 | 15.9 | 3/8 | M10 | UCX05-16 UCX05 |

FX05 | 1.02 | |

| UCFX06-19 UCFX06-20 UCFX06 |

1-3/16 1-1/4 |

30 | 117 | 92 | 19 | 14.3 | 34 | 16 | 44.4 | 49.2 | 17.5 | 1/2 | 14 | UCX06-19 UCX06-20 UCX06 |

FX06 | 1.46 |

| UCFX07-22 UCFX07-23 UCFX07 |

1-3/8 1-7116 |

35 | 130 | 102 | 21 | 14.3 | 38 | 16 | 51.2 | 49.2 | 19 | 1/2 | M14 | UCX07-22 UCXX07-23 UCX07 |

FX07 | 1.94 |

| UCFX08-24 UCFX08 |

1-1/2 | 40 | 137 | 105 | 22 | 14.3 | 40 | 19 | 52.2 | 49.2 | 19 | 5/8 | M16 | UCX08-24 UCX08 |

FX08 | 2.2 |

| UCFX09-26 UCFX09-27 UCFX09-28 UCFX09 |

1-5/8 1-11/16 1-3/4 |

45 | 143 | 111 | 23 | 14.3 | 40 | 19 | 55.6 | 51.6 | 19 | 5/8 | M16 | UCX09-28 UCX09-27 UCX 09-28 UCX09 |

FX09 | 2.42 |

| UCFX10-31 UCFX10-32 UCFX10 |

1-15/16 2 |

50 | 162 | 130 | 26 | 20 | 44 | 19 | 59.4 | 55.6 | 22.2 | 5/8 | M16 | UCX10-31 UCX 10-32 UCX10 |

FX10 | 3.41 |

| UCFX11-35 UCFX11-36 UCFX11 |

2-3/16 2-1/4 |

55 | 175 | 143 | 29 | 20 | 49 | 19 | 68.7 | 65.1 | 25.4 | 5/8 | M16 | UCX11-35 UCX 11-36 UCX11 |

FX11 | 4.52 |

| UCFX12-38 UCFX12-39 UCFX12 |

2-3/8 2-7/16 |

60 | 187 | 149 | 34 | 21 | 59 | 19 | 73.7 | 65.1 | 25.4 | 5/8 | M16 | JCX12-38 UCX 12-39 UCX12 |

FX12 | 5.32 |

| UCFX13-40 UCFX13 |

2-1/2 | 65 | 187 | 149 | 34 | 21 | 59 | 19 | 78.4 | 74.6 | 30.2 | 5/8 | M16 | UCX13-40 UCX13 |

FX13 | 5.53 |

| UCFX14-44 UCFX14 |

2-3/4 | 70 | 197 | 152 | 37 | 24 | 60 | 23 | 81.5 | 77.8 | 33.3 | 3/4 | M20 | UCX14-44 UCX14 |

FX14 | 6.77 |

| UCFX15-47 UCFX15-48 UCFX15 |

2-15/16 3 |

75 | 197 | 152 | 40 | 24 | 68 | 23 | 89.3 | 826 | 33.3 | 3/4 | M20 | UCX15-47 UCX15-48 UCX15 |

FX15 | 7.82 |

| CEX16-50 UCFX16 |

3-1/8 | 80 | 214 | 171 | 40 | 24 | 70 | 23 | 91.6 | 85.7 | 34.1 | 3/4 | M20 | UCX16-50 UCX16 |

FX16 | 8.91 |

| UCFX17-55 UCFX17 |

3-7/16 | 85 | 214 | 171 | 40 | 24 | 70 | 23 | 96.3 | 96 | 39.7 | 3/4 | M20 | UCX17-55 UCX17 |

FX17 | 10.23 |

| UCFX18-56 UCFX18 |

3-1/2 | 90 | 214 | 171 | 45 | 24 | 76 | 23 | 106.1 | 104 | 429 | 3/4 | M20 | UCX18-56 UCX18 |

FX18 | 11.89 |

| UCFX20-63 UCFX20-64 UCFX20 |

3-15/16 4 |

100 | 268 | 211 | 59 | 31 | 97 | 31 | 127.3 | 117.5 | 49.2 | 1-1/8 | M27 | UCX20-63 UCX20-64 JCX20 |

FX20 | 19.44 |

UCCF200

| Bearing Unit NO | Shaft Dia d |

Dimensions(mm) | Bolt Used | Beaning No |

Housing No | Housing Wt (kg |

||||||||

| (in) | (mm) | a | e | i | 5 | Z | Bi | n | mm | in | ||||

| UCCF201-8 UCCF202-9 UCCF202-10 UCCF203-11 UCCF204-12 UCCF20 UCCF202 UCCF203 UCCF204 |

1/2 9/16 5/8 11/16 314 |

12 15 17 20 |

86 | 64 | 15 | 12 | 46 | 31 | 12.7 | M10 | 38 | UC201-8 UC202-9 UC202-10 UC203-11 UC204-12 UC201 UC202 UC203 UC204 |

CF201 CF202 CF203 CF204 |

0.84 |

| UCCF205-13 UCCF205-14 UCCF205-15 UCCF205-16 UCCF205 |

13/16 7/8 15/16 1 |

25 | 95 | 70 | 16 | 12 | 51 | 34.1 | 14.3 | M10 | 318 | UC205-13 UC205-14 UC205-15 UC205-16 UC205 |

CF205 | 1 |

| UCCF206-17 | 1-1/16 | UC206-17 | ||||||||||||

| UCCF206-18 | 1-1/8 | UC206-18 | ||||||||||||

| UCCF206-19 | 1-3/16 | 108 | 83 | 18 | 12 | 55 | 38.1 | 15.9 | M10 | 3/8 | UC206-19 | CF206 | 1.29 | |

| UCCF206-20 | 1-1/4 | UC206-20 | ||||||||||||

| UCCF206 | 30 | UC206 | ||||||||||||

| UCCF207-20 UCCF207-21 UCCF207-22 UCCF207-23 UCCF207 |

1-1/4 1-5/16 1-3/8 1-7/16 |

35 | 117 | 92 | 19 | 14 | 59 | 42.9 | 17.5 | M12 | 7/16 | UC207-20 UC207-21 UC207-22 UC207-23 UC207 |

CF207 | 1.61 |

| UCCF208-24 UCCF208-25 UCCF208 |

1-1/2 1-9/16 |

40 | 130 | 102 | 21 | 16 | 686 | 49.2 | 19 | M14 | 1/2 | UC208-24 UC208-25 UC208 |

CF208 | 2.07 |

| UCCF209-26 UCCF209-27 UCCF209-28 UCCF209 |

1.88 1-11/16 1-3/4 |

45 | 137 | 105 | 22 | 16 | 67 | 49.2 | 19 | M14 | 1/2 | UC209-26 UC209-27 UC209-28 UC209 |

CF209 | 2.42 |

| UCCF210-29 UCCF210-30 UCCF210-31 UCCF210-32 UCCF210 |

1-13/16 1-7/8 1-15/16 |

50 | 143 | 111 | 22 | 16 | 71 | 51.6 | 19 | M14 | 1/2 | UC210-29 UC210-30 UC210-31 UC210-32 UC210 |

CF210 | 2.81 |

| UCCF211-32 UCCF211-33 UCCF211-34 UCCF211-35 UCCF211 |

2-1/16 2-1/8 2-3/16 |

55 | 162 | 130 | 25 | 19 | 75 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 UC211-33 UC211-34 UC211-35 UC211 |

CF211 | 3.56 |

| UCCF212-36 | 2-1/4 | UC212-36 | ||||||||||||

| UCCF212-37 | 2-5/16 | UC212-37 | ||||||||||||

| UCCF212-38 | 2-3/8 | 175 | 143 | 29 | 19 | 86 | 65.1 | 25.4 | M16 | 518 | UC212-38 | CF212 | 4.43 | |

| UCCF212-39 | 2-7/16 | UC212-39 | ||||||||||||

| UCCF212 | 60 | UC212 | ||||||||||||

| UCCF213-40 UCCF213-41 UCCF213 |

2-1/2 2-9/16 |

65 | 187 | 149 | 30 | 19 | 89 | 65.1 | 25.4 | M16 | 518 | UC213-40 UC213-41 UC213 |

CF213 | 5.37 |

| UCCF214-42 UCCF214-43 UCCF214-44 UCCF214 |

2-518 2-11/16 2-3/4 |

70 | 193 | 152 | 31 | 19 | 98 | 74.6 | 30.2 | M16 | 518 | UC214-42 UC214-43 UC214-44 UC214 |

CF214 | 5.72 |

| UCCF215-45 UCCF215-46 UCCF215-47 UCCF215-48 UCCF215 |

2-13/16 2-7/8 2-15/16 3 |

75 | 200 | 159 | 34 | 19 | 102 | 77.8 | 33.3 | M16 | 518 | UC215-45 UC215-46 UC215-47 UC215-48 UC215 |

CF215 | 6.35 |

| UCCF216-50 UCCF216 |

3-/8 | 80 | 208 | 165 | 34 | 23 | 107 | 82.6 | 33.3 | M20 | 3/4 | UC216-50 UC216 |

CF216 | 7.14 |

| UCCF217-52 UOCF217 |

3-1/4 | 85 | 220 | 175 | 36 | 23 | 111 | 85.7 | 34.1 | M20 | 3/4 | UC217-52 UC217 |

CF217 | 8.38 |

| UCCF218-56 JCCF218 |

3-1/2 | 90 | 235 | 187 | 40 | 23 | 122 | 96 | 39.7 | M20 | 3/4 | UC218-56 UC218 |

CF218 | 10.5 |

Product Application

Transportation field:

Pillow block bearing are widely used in transportation equipment, such as cars, trains, locomotives, ships, and so on.

Industrial production field:

Pillow block bearing are also widely used in various production equipment, such as injection molding machines, rubber machines, food machinery, and so on.

Mechanical equipment field:

Pillow block bearing are widely used in various types of mechanical equipment, such as machine tools, agricultural machinery, construction machinery, metallurgical equipment, papermaking machinery, and so on.

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer?

A: We are bearing manufacturer.

Q: How do you control quality of bearing?

A: All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: The lead time for sample orders is 3-5 days, for bulk orders is 5-20 days., depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

e /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Raceway: | Spherical Raceway |

|---|---|

| Material: | Bearing Steel |

| Bearing Block Model: | P |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do pillow block bearings contribute to the proper functioning of food processing equipment?

Pillow block bearings play a crucial role in ensuring the proper functioning of food processing equipment. They provide reliable support and smooth operation for rotating shafts and components in various stages of food processing. Here are the key contributions of pillow block bearings to the proper functioning of food processing equipment:

- Sanitary Design:

- Reliable Performance:

- Corrosion Resistance:

- Contamination Prevention:

- Easy Maintenance:

- Versatility:

In food processing environments, maintaining strict hygiene standards is essential. Pillow block bearings designed for food processing equipment are constructed with materials and features that adhere to sanitary requirements. They are often made from stainless steel or other corrosion-resistant materials that are easy to clean and withstand frequent washdowns. Additionally, these bearings have smooth surfaces, rounded edges, and minimal crevices to prevent the accumulation of food particles, debris, or bacteria. The sanitary design of pillow block bearings ensures the integrity and cleanliness of the equipment, minimizing the risk of contamination and ensuring compliance with food safety regulations.

Food processing equipment operates under demanding conditions, including high production rates, heavy loads, and frequent start-stop cycles. Pillow block bearings are designed to withstand these challenges and provide reliable performance. They offer excellent load-bearing capacity, shock resistance, and vibration damping capabilities. This ensures smooth and stable operation of rotating shafts, reducing the risk of equipment failure, downtime, and production interruptions. By contributing to the reliable performance of food processing equipment, pillow block bearings support efficient and uninterrupted food processing operations.

Food processing environments often involve exposure to moisture, chemicals, and cleaning agents. Pillow block bearings designed for food processing equipment are highly resistant to corrosion and chemical attack. They are made from materials that can withstand the corrosive effects of food acids, cleaning solutions, and other substances encountered in the processing area. The corrosion resistance of these bearings helps maintain their structural integrity, extends their lifespan, and ensures reliable performance even in harsh operating conditions.

Preventing contamination is of utmost importance in food processing. Pillow block bearings incorporate sealing mechanisms, such as rubber seals or labyrinth seals, to prevent the entry of contaminants into the bearing housing. These seals provide a barrier against dirt, dust, moisture, and other external elements, minimizing the risk of contamination of the food products. The effective sealing of pillow block bearings helps maintain the cleanliness and purity of the processing environment, safeguarding the quality and safety of the food products.

Maintenance and cleanliness are critical in food processing equipment. Pillow block bearings are designed for easy maintenance, inspection, and cleaning. They often have features such as grease fittings or lubrication access points that facilitate the replenishment of lubricants without disassembling the bearing. This simplifies routine maintenance tasks and allows for timely lubrication, ensuring optimal bearing performance. The ease of maintenance of pillow block bearings contributes to the overall efficiency and reliability of food processing equipment.

Food processing equipment encompasses a wide range of applications, such as mixing, grinding, conveying, and packaging. Pillow block bearings offer versatility and can be used in various equipment types and configurations. They are available in different sizes, load capacities, and mounting options to accommodate the specific requirements of different food processing applications. The versatility of pillow block bearings allows for their integration into diverse equipment designs, supporting the proper functioning of food processing machinery.

In summary, pillow block bearings contribute to the proper functioning of food processing equipment by offering a sanitary design, ensuring reliable performance, providing corrosion resistance, preventing contamination, enabling easy maintenance, and offering versatility. By fulfilling these roles, pillow block bearings support the efficient, hygienic, and uninterrupted operation of food processing equipment while maintaining the highest standards of food safety and quality.

How do pillow block bearings enhance the performance of agricultural machinery like tractors?

Pillow block bearings play a vital role in enhancing the performance of agricultural machinery, including tractors. Their contributions to the functionality and efficiency of tractors can be outlined as follows:

- Support and Load Handling:

- Reduced Friction and Wear:

- Alignment and Stability:

- Contamination Protection:

- Maintenance and Accessibility:

Pillow block bearings provide essential support for the rotating shafts and other moving components in agricultural machinery, such as tractors. They handle and transmit the loads applied to the machinery, including the weight of the equipment, implements, and the forces encountered during operation. By effectively supporting the shafts and components, pillow block bearings help maintain the structural integrity of the machinery and ensure smooth and efficient movement, contributing to overall performance.

Pillow block bearings are designed to minimize friction between the rotating shafts and the bearing housing, reducing energy losses and wear. By incorporating rolling elements, such as balls or rollers, pillow block bearings facilitate smooth motion with reduced friction. This friction reduction results in improved energy efficiency, reduced power consumption, and extended lifespan of the bearings and other related components in the agricultural machinery like tractors.

Proper alignment of the components is crucial for the efficient operation of agricultural machinery, including tractors. Pillow block bearings aid in aligning and supporting the shafts and other moving parts, ensuring they remain centered and in the correct position. This alignment helps prevent excessive vibrations, reduces the risk of misalignment-related issues, and promotes stable and consistent performance, enhancing the overall functionality of tractors.

Agricultural environments can be harsh, with exposure to dust, dirt, moisture, and other contaminants. Pillow block bearings are designed to provide protection against these contaminants. They often incorporate sealing mechanisms, such as rubber seals or labyrinth seals, to prevent the entry of foreign particles into the bearing. This protection helps maintain the cleanliness of the bearing’s internal components, reducing the risk of premature wear, corrosion, or damage, and contributing to the reliable and efficient operation of tractors.

Maintenance is an essential aspect of ensuring the performance and longevity of agricultural machinery like tractors. Pillow block bearings are designed with ease of maintenance in mind. They often feature a split housing design that allows for convenient access to the bearing without the need to disassemble the entire machinery. This accessibility simplifies maintenance tasks, reduces downtime, and promotes efficient upkeep of the bearings, contributing to the overall performance and reliability of tractors.

In summary, pillow block bearings enhance the performance of agricultural machinery like tractors by providing support, handling loads, reducing friction and wear, ensuring alignment and stability, protecting against contaminants, and offering ease of maintenance. With their crucial role in supporting and facilitating the movement of shafts and components, pillow block bearings optimize the performance, energy efficiency, and lifespan of agricultural machinery, contributing to improved productivity and reliability in farming operations.

What advantages do pillow block bearings offer compared to other types of bearings?

Pillow block bearings, also known as plummer block bearings, offer several advantages compared to other types of bearings. These advantages make them a popular choice in various industrial applications. Here’s a detailed explanation of the advantages of pillow block bearings:

- Easy Installation:

- Self-Aligning Capability:

- Load Support:

- Environmental Protection:

- Versatility and Adaptability:

- Easy Maintenance:

Pillow block bearings are designed for easy installation. The split housing allows for quick assembly and disassembly without the need to remove other components or disassemble the entire system. This feature simplifies bearing replacement, lubrication, and inspection, reducing downtime and maintenance costs.

Pillow block bearings are designed to accommodate slight misalignments or shaft deflections. This self-aligning capability helps to ensure smooth operation and reduce stress on the bearing. It allows for more flexibility in the installation process and helps compensate for any misalignment that may occur during operation.

Pillow block bearings are capable of handling both radial and axial loads, depending on the type of bearing insert used. This load-carrying capacity makes them suitable for a wide range of applications where there are varying load requirements. They provide reliable support for rotating shafts and help transmit loads between the shaft and the housing.

Pillow block bearings offer a degree of environmental protection to the bearing insert. The housing acts as a shield, preventing contaminants such as dust, dirt, and moisture from entering the bearing and causing premature failure. This protection helps to extend the service life of the bearing and improve overall reliability.

Pillow block bearings are highly versatile and adaptable to various industrial applications. They can be found in a wide range of industries, including manufacturing, mining, agriculture, construction, and material handling. These bearings are used in conveyor systems, power transmission equipment, pumps, fans, compressors, and many other rotating machinery applications.

Due to their design, pillow block bearings are easy to maintain. The split housing simplifies lubrication, inspection, and replacement of the bearing insert. This ease of maintenance reduces downtime and allows for efficient servicing of the bearing, contributing to improved operational efficiency.

In summary, pillow block bearings offer several advantages compared to other types of bearings. These advantages include easy installation and maintenance, self-aligning capability, load support, environmental protection, versatility, and adaptability. These features make pillow block bearings a reliable and efficient choice for various industrial applications where ease of installation, flexibility, and durability are important factors.

editor by CX 2024-05-14

China best Bearing Housing Unit UC 207 UCP 206 Ucf 205 Ucf 204 Pillow Block Bearing for Agricultural Machinery Bearing double row ball bearing

Product Description

| Rows Number | Single | Load Direction | Radial Bearing |

| Material | Bearing Steel | Precision Rating | PO P6 P5 P4 P2 |

| Clearance | CO C1 C2 C3 C4 | Lubrication | Oil Lubrication |

| OEM | Available | Hardness | 59-63HRC |

| Feature | High Speed,Long Life | Transport Package | Single Box |

| Specification | standard | Trademark | Packing |

| Production Capacity | 1500,000 Pieces/Year |

The outer spherical ball bearing is actually a variant of the deep groove ball bearing. Its characteristic is that its outer ring outer diameter surface is a spherical surface, which can be fitted into the corresponding concave spherical surface of the bearing seat to play the role of centering. The outer spherical bearing is mainly used to bear the combined radial and axial load based on the radial load, and it is generally not suitable to bear the axial load alone.

| UC200 series | ||||||||||||

| Bearing type | Dimensions(mm) | Weight(KG) | basic load capacity(KN) | Limt speed(r/min) | ||||||||

| d | D | B | C | S | G | H | ds | dynamic | static | |||

| UC201 | 12 | 40 | 27.4 | 14 | 11.5 | 4.5 | 4 | M*0.75 | 0.12 | 7.36 | 4.48 | 4000 |

| UC202 | 15 | 40 | 27.4 | 14 | 11.5 | 4.5 | 4 | M*0.75 | 0.11 | 7.36 | 4.48 | 4000 |

| UC203 | 17 | 40 | 27.4 | 14 | 11.5 | 4.5 | 4 | M*0.75 | 0.1 | 7.36 | 4.48 | 4000 |

| UC204 | 20 | 47 | 31 | 17 | 12.7 | 4.7 | 4.5 | M6*1.0 | 0.16 | 9.88 | 6.2 | 4000 |

| UC205 | 25 | 52 | 34.1 | 17 | 14.3 | 5.5 | 4.7 | M6*1.0 | 0.19 | 10.78 | 6.98 | 3400 |

| UC206 | 30 | 62 | 38.1 | 19 | 15.9 | 6 | 4.5 | M6*1.0 | 0.31 | 14.97 | 10.04 | 2800 |

| UC207 | 35 | 72 | 42.9 | 20 | 17.5 | 6.5 | 5.1 | M8*1.0 | 0.48 | 19.75 | 13.67 | 2400 |

| UC208 | 40 | 80 | 49.2 | 21 | 19 | 8 | 5.8 | M8*1.0 | 0.62 | 22.71 | 15.94 | 2200 |

| UC209 | 45 | 85 | 49.2 | 22 | 19 | 8 | 6.2 | M8*1.0 | 0.67 | 24.36 | 17.71 | 1900 |

| UC210 | 50 | 90 | 51.6 | 23 | 19 | 9 | 6.5 | M10*1.0 | 0.78 | 26.98 | 19.84 | 1800 |

| UC211 | 55 | 100 | 55.6 | 25 | 22.2 | 9 | 7.3 | M10*1.0 | 1.03 | 33.37 | 25.11 | 1600 |

| UC212 | 60 | 110 | 65.1 | 27 | 25.4 | 11 | 7.7 | M10*1.0 | 1.45 | 36.74 | 27.97 | 1500 |

| UC213 | 65 | 120 | 65.1 | 28 | 25.4 | 12 | 8.3 | M10*1.0 | 1.71 | 44.01 | 34.18 | 1400 |

| UC214 | 70 | 125 | 74.6 | 30 | 30.2 | 12 | 8.7 | M12*1.25 | 2.06 | 46.79 | 37.59 | 1300 |

| UC215 | 75 | 130 | 77.8 | 30 | 33.3 | 12 | 9.2 | M12*1.25 | 2.22 | 50.85 | 41.26 | 1200 |

| UC216 | 80 | 140 | 82.6 | 33 | 33.3 | 14 | 9.6 | M12*1.25 | 2.8 | 55.04 | 45.09 | 1100 |

| UC217 | 85 | 150 | 85.7 | 36 | 34.1 | 14 | 10.5 | M12*1.25 | 3.48 | 64.01 | 53.28 | 1000 |

| UC218 | 90 | 160 | 96 | 37 | 39.7 | 14 | 11.1 | M12*1.25 | 4.3 | 73.83 | 60.76 | 950 |

| UC 300series | ||||||||||||

| Bearing type | Dimensions(mm) | Weight(KG) | basic load capacity(KN) | Limt speed(r/min) | ||||||||

| d | D | B | C | S | G | H | ds | dynamic | static | |||

| UC305 | 25 | 62 | 38 | 21 | 15 | 6 | 6.1 | M6*1 | 0.35 | 17.22 | 11.39 | 2800 |

| UC306 | 30 | 72 | 43 | 23 | 17 | 6 | 6.7 | M8*1 | 0.56 | 20.77 | 14.17 | 2600 |

| UC307 | 35 | 80 | 48 | 25 | 19 | 8 | 7.4 | M8*1 | 0.71 | 25.66 | 17.92 | 2200 |

| UC308 | 40 | 90 | 52 | 27 | 22 | 10 | 8.2 | M10*1 | 0.96 | 31.35 | 22.38 | 2000 |

| UC309 | 45 | 100 | 57 | 30 | 22 | 10 | 9 | M10*1 | 1.28 | 40.66 | 30 | 1800 |

| UC310 | 50 | 110 | 61 | 32 | 25 | 12 | 10 | M12*1.25 | 1.65 | 47.58 | 35.71 | 1700 |

| UC311 | 55 | 120 | 66 | 34 | 26 | 12 | 10.7 | M12*1.25 | 1.9 | 55.05 | 41.91 | 1400 |

| UC312 | 60 | 130 | 71 | 36 | 30 | 12 | 11.5 | M12*1.25 | 2.6 | 62.88 | 48.6 | 1300 |

| UC313 | 65 | 140 | 75 | 38 | 33 | 12 | 12.2 | M12*1.25 | 3.15 | 72.21 | 56.68 | 1200 |

| UC314 | 70 | 150 | 78 | 40 | 33 | 14 | 13 | M12*1.25 | 3.83 | 80.1 | 63.48 | 1100 |

| UC315 | 75 | 160 | 82 | 42 | 33 | 14 | 13.8 | M14*1.5 | 4.59 | 87.25 | 71.68 | 1000 |

| UC316 | 80 | 170 | 86 | 44 | 34 | 14 | 14.5 | M16*1.5 | 5.3 | 94.57 | 80.35 | 1000 |

| UC317 | 85 | 180 | 96 | 46 | 40 | 16 | 15 | M16*1.5 | 6.58 | 102.25 | 89.52 | 9050 |

| UC318 | 90 | 190 | 96 | 48 | 40 | 16 | 15.9 | M16*1.5 | 7.5 | 110.81 | 100.76 | 900 |

| UC319 | 95 | 200 | 103 | 50 | 41 | 16 | 16.7 | M16*1.5 | 8.7 | 120.51 | 113.75 | 850 |

| UC320 | 100 | 215 | 108 | 54 | 42 | 18 | 18 | M16*1.5 | 10.8 | 133.06 | 131.18 | 800 |

| Deep groove ball bearing | ||||

| Bearing type | Dimensions(mm) | Weight(kg) | ||

| Inner diameter | Outer diameter | breadth | ||

| 16001 | 12 | 28 | 7 | 0.019 |

| 16002 | 15 | 32 | 8 | 0.571 |

| 16003 | 17 | 35 | 8 | 0.033 |

| 16004 | 20 | 42 | 8 | 0.048 |

| 16005 | 25 | 47 | 8 | 0.059 |

| 16006 | 30 | 55 | 9 | 0.087 |

| 16007 | 35 | 62 | 99 | 0.107 |

| 16008 | 40 | 68 | 10 | 0.13 |

| 16009 | 45 | 75 | 10 | 0.167 |

| 16571 | 50 | 80 | 11 | 0.175 |

| 16011 | 55 | 90 | 11 | 0.257 |

| 16012 | 60 | 95 | 11 | 0.281 |

| 16013 | 65 | 100 | 13 | 0.3 |

| 16014 | 70 | 110 | 13 | 0.437 |

| 16015 | 75 | 115 | 14 | 0.463 |

| 16016 | 80 | 125 | 14 | 0.621 |

| 16017 | 85 | 130 | 16 | 0.652 |

| 16018 | 90 | 140 | 16 | 0.87 |

| 16019 | 95 | 145 | 16 | 0.904 |

| Bearing type | Dimensions(mm) | Weight(kg) | ||

| Inner diameter | Outer diameter | breadth | ||

| 16571 | 100 | 150 | 8 | 0.945 |

| 6000 | 10 | 26 | 8 | 0.018 |

| 6001 | 12 | 28 | 9 | 0.571 |

| 6002 | 15 | 32 | 10 | 0.031 |

| 6003 | 17 | 35 | 12 | 0.041 |

| 6004 | 20 | 42 | 12 | 0.068 |

| 6005 | 25 | 47 | 13 | 0.079 |

| 6006 | 30 | 55 | 14 | 0.116 |

| 6007 | 35 | 62 | 15 | 0.151 |

| 6008 | 40 | 68 | 16 | 0.19 |

| 6009 | 45 | 75 | 16 | 0.241 |

| 6571 | 50 | 80 | 18 | 0.261 |

| 6011 | 55 | 90 | 18 | 0.381 |

| 6012 | 60 | 95 | 18 | 0.412 |

| 6013 | 65 | 100 | 20 | 0.439 |

| 6014 | 70 | 110 | 20 | 0.608 |

| 6015 | 75 | 115 | 22 | 0.649 |

| 6016 | 80 | 125 | 22 | 0.872 |

| 6017 | 85 | 130 | 24 | 0.918 |

| 6018 | 90 | 140 | 24 | 1.19 |

More series of deep groove ball bearing

6300 series deep groove ball bearing

6220 series deep groove ball bearing

Production Line

HangZhou Siruibo Bearing Technology Co., Ltd. is a company mainly engaged in manufacturing and selling outer spherical bearings. The registered capital is Five million.

Since its establishment 20 years ago, the company is committed to Mounted Bearing Unit (maintenance-free bearings, engraving machine bearings, holding machine shaft Bearing, no-tillage machine bearing, fan bearing, high temperature bearing, zinc alloy bearing, food grade bearing unit) research and development. With the most complete varieties and best advanced manufacturing technology in production of Mounted Bearing Unit, to be a reliable enterprises, we welcome your cooperation. Currently, our company produce 10 series of more than 260 varieties of outer spherical bearings and 13 different structural categories of outer spherical bearing special seats, all adopted International standard design and manufacturing. Registered trademark “FOS” .

Through the efforts and unremitting pursuit of all employees of the company, all products accepted by international standards. Over the years of Expansion and technical transformation, we developed into a Mounted Bearing Unit with large scale of professional manufacturers, for the bearing industry in China, has made a contribution to the development of Bearing.

HangZhou Siruibo Bearing Technology Co., Ltd. has a production capacity of 1 million sets/year, with an annual output value of 30 million yuan. We produce 30 varieties monthly , with 45-60 days lead time.

The company has a perfect material and product quality inspection equipment, according to the strict scientific Quality assurance system, to prove satisfactory to our customers. Our products widely used in agricultural Industry machinery, textile machinery and light industry, chemical industry, metallurgy, printing, food, transportation, coal, packaging and other industries and the introduction of machinery .Our products have exported to Europe, America and many countries and regions in South east Asia.

Exhibitions

About us:

We are 1 manufactuer of bearing for more than 20 years.

Give us a chance, we will cooperate with our passion.

Our professional, reliable, experienced products and service can meet your request.

Why choose us?

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS mix different standard bearings.

2. MOQ: 3000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our bearings website, we strongly encourge that you can communicate with us through email, thanks!

We have all kinds of bearings, just tell me your item number and quantity, best price will be offered to you soon

The material of the bearings, precision rating, seals type, OEM service, etc, all of them we can make according to your requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small (28-55mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do pillow block bearings contribute to the proper functioning of food processing equipment?

Pillow block bearings play a crucial role in ensuring the proper functioning of food processing equipment. They provide reliable support and smooth operation for rotating shafts and components in various stages of food processing. Here are the key contributions of pillow block bearings to the proper functioning of food processing equipment:

- Sanitary Design:

- Reliable Performance:

- Corrosion Resistance:

- Contamination Prevention:

- Easy Maintenance:

- Versatility:

In food processing environments, maintaining strict hygiene standards is essential. Pillow block bearings designed for food processing equipment are constructed with materials and features that adhere to sanitary requirements. They are often made from stainless steel or other corrosion-resistant materials that are easy to clean and withstand frequent washdowns. Additionally, these bearings have smooth surfaces, rounded edges, and minimal crevices to prevent the accumulation of food particles, debris, or bacteria. The sanitary design of pillow block bearings ensures the integrity and cleanliness of the equipment, minimizing the risk of contamination and ensuring compliance with food safety regulations.

Food processing equipment operates under demanding conditions, including high production rates, heavy loads, and frequent start-stop cycles. Pillow block bearings are designed to withstand these challenges and provide reliable performance. They offer excellent load-bearing capacity, shock resistance, and vibration damping capabilities. This ensures smooth and stable operation of rotating shafts, reducing the risk of equipment failure, downtime, and production interruptions. By contributing to the reliable performance of food processing equipment, pillow block bearings support efficient and uninterrupted food processing operations.

Food processing environments often involve exposure to moisture, chemicals, and cleaning agents. Pillow block bearings designed for food processing equipment are highly resistant to corrosion and chemical attack. They are made from materials that can withstand the corrosive effects of food acids, cleaning solutions, and other substances encountered in the processing area. The corrosion resistance of these bearings helps maintain their structural integrity, extends their lifespan, and ensures reliable performance even in harsh operating conditions.

Preventing contamination is of utmost importance in food processing. Pillow block bearings incorporate sealing mechanisms, such as rubber seals or labyrinth seals, to prevent the entry of contaminants into the bearing housing. These seals provide a barrier against dirt, dust, moisture, and other external elements, minimizing the risk of contamination of the food products. The effective sealing of pillow block bearings helps maintain the cleanliness and purity of the processing environment, safeguarding the quality and safety of the food products.

Maintenance and cleanliness are critical in food processing equipment. Pillow block bearings are designed for easy maintenance, inspection, and cleaning. They often have features such as grease fittings or lubrication access points that facilitate the replenishment of lubricants without disassembling the bearing. This simplifies routine maintenance tasks and allows for timely lubrication, ensuring optimal bearing performance. The ease of maintenance of pillow block bearings contributes to the overall efficiency and reliability of food processing equipment.

Food processing equipment encompasses a wide range of applications, such as mixing, grinding, conveying, and packaging. Pillow block bearings offer versatility and can be used in various equipment types and configurations. They are available in different sizes, load capacities, and mounting options to accommodate the specific requirements of different food processing applications. The versatility of pillow block bearings allows for their integration into diverse equipment designs, supporting the proper functioning of food processing machinery.

In summary, pillow block bearings contribute to the proper functioning of food processing equipment by offering a sanitary design, ensuring reliable performance, providing corrosion resistance, preventing contamination, enabling easy maintenance, and offering versatility. By fulfilling these roles, pillow block bearings support the efficient, hygienic, and uninterrupted operation of food processing equipment while maintaining the highest standards of food safety and quality.

How do pillow block bearings contribute to the efficient operation of conveyor systems?

Pillow block bearings play a crucial role in ensuring the efficient operation of conveyor systems. Their contributions can be outlined as follows:

- Support and Load Handling:

- Reduced Friction and Wear:

- Alignment and Stability:

- Protection and Contamination Prevention:

- Maintenance and Accessibility:

Pillow block bearings provide support for the rotating shafts in conveyor systems. They are responsible for handling and transmitting the loads applied to the conveyor, including the weight of the conveyed material and any external forces. By effectively supporting the shaft, pillow block bearings help maintain the structural integrity of the conveyor and ensure smooth and efficient movement of the material.

Pillow block bearings are designed to minimize friction between the rotating shaft and the bearing housing. They incorporate rolling elements, such as balls or rollers, which facilitate smooth motion with reduced friction. By reducing friction and wear, pillow block bearings help optimize the energy efficiency of the conveyor system, minimizing power consumption and extending the lifespan of the bearings and other related components.

Proper alignment of the conveyor components is essential for efficient operation. Pillow block bearings aid in aligning and supporting the shaft, ensuring that it remains centered and in the correct position. This alignment helps prevent excessive vibrations, reduces the risk of misalignment-related issues, and promotes stable and consistent performance of the conveyor system.

Pillow block bearings are designed to provide protection against contaminants, moisture, and debris in the operating environment. They often incorporate sealing mechanisms, such as rubber seals or labyrinth seals, to prevent the entry of foreign particles into the bearing. This protection helps maintain the cleanliness of the bearing’s internal components, reducing the risk of premature wear, corrosion, or damage. By preventing contamination, pillow block bearings contribute to the efficient and reliable operation of the conveyor system.

Conveyor systems require periodic maintenance, including bearing inspection, lubrication, and potential replacement. Pillow block bearings are designed with ease of maintenance in mind. They often feature a split housing design that allows for convenient access to the bearing without disassembling the entire conveyor system. This accessibility simplifies maintenance tasks, reduces downtime, and promotes efficient upkeep of the bearings, ensuring the long-term reliability and performance of the conveyor system.

In summary, pillow block bearings contribute to the efficient operation of conveyor systems by providing support, handling loads, reducing friction and wear, ensuring alignment and stability, protecting against contaminants, and offering ease of maintenance. With their essential role in supporting and facilitating the movement of conveyor shafts, pillow block bearings help optimize the performance, energy efficiency, and longevity of conveyor systems.

What are pillow block bearings and how are they used in various industrial applications?

Pillow block bearings, also known as plummer block bearings, are a type of bearing mounted inside a housing or block, typically made of cast iron or pressed steel. These bearings are widely used in various industrial applications due to their versatility and ease of installation. Here’s a detailed explanation of pillow block bearings and their uses:

- Design and Construction:

- Supporting Shaft Loads:

- Easy Installation and Maintenance:

- Versatility and Adaptability:

- Environmental Protection:

- Specialized Variations:

A pillow block bearing consists of a bearing insert (such as a deep groove ball bearing, spherical roller bearing, or cylindrical roller bearing) and a housing or block. The housing is typically a split design that allows for easy installation and maintenance. It usually has a flat base with mounting holes for attachment to a support structure, such as a machine frame or conveyor system. The bearing insert is pre-mounted inside the housing and provides the rotating element to support shafts or other moving parts.

Pillow block bearings are primarily used to support rotating shafts and transmit loads between the shaft and the housing. They are capable of handling both radial and axial loads, depending on the type of bearing insert used. The design of the pillow block bearing allows for self-aligning capability, which helps accommodate slight misalignments or shaft deflections, ensuring smooth operation and reducing stress on the bearing.

One of the key advantages of pillow block bearings is their ease of installation and maintenance. The split housing design allows for quick assembly and disassembly without the need to remove other components or disassemble the entire system. This feature simplifies bearing replacement, lubrication, and inspection, reducing downtime and maintenance costs in industrial applications.

Pillow block bearings are highly versatile and adaptable to various industrial applications. They can be found in a wide range of industries, including manufacturing, mining, agriculture, construction, and material handling. These bearings are used in conveyor systems, power transmission equipment, pumps, fans, compressors, and many other rotating machinery applications.

Pillow block bearings are designed to provide a degree of environmental protection to the bearing insert. The housing acts as a shield, preventing contaminants such as dust, dirt, and moisture from entering the bearing and causing premature failure. Additionally, the housing design often includes provisions for grease or oil lubrication, further protecting the bearing and ensuring proper lubrication for optimal performance.

While the basic design of pillow block bearings remains the same, there are specialized variations available to meet specific application requirements. These include corrosion-resistant bearings for harsh environments, high-temperature bearings for elevated temperature applications, and sealed bearings for applications where additional protection against contamination is needed.

In summary, pillow block bearings are bearing units housed in a block or housing, widely used in various industrial applications. They provide support for rotating shafts, transmit loads, accommodate misalignments, and offer easy installation and maintenance. Their versatility, adaptability, and environmental protection make them suitable for diverse industrial sectors. With specialized variations available, pillow block bearings can be customized to meet specific application needs, ensuring reliable and efficient operation in a wide range of industrial machinery and equipment.

editor by CX 2024-05-07

China best Pillow Block Bearings Housing Bearing UCP206 with high quality

Product Description

Product Description

Introduce our outer spherical bearings to meet your business needs!

Are you looking for outer spherical bearings to improve the performance of your industrial machinery? Look no more! Our outer spherical bearing design offers unmatched advantages.

1. Exceptional Load Capacity: Our bearings are designed to handle heavy axial loads with ease, ensuring the reliable operation of your equipment even in the most demanding environments.

2. Precision Engineering: Crafted with precision and attention to detail, these bearings offer outstanding accuracy and minimal friction, contributing to the efficiency and longevity of your machines.

3. Reduced downtime: With our outer spherical bearings, you can count on reduced downtime and maintenance costs, keeping your business productive and profitable.

4. Versatile Applications: Whether you’re in the automotive, aerospace, manufacturing, or any other

Product Parameters

| Product Name | UCP outer spherical bearing |

| Brand Name | KSA |

| Material | Gcr15 |

| Precision Grade | P0,P6,P5 |

| Certification | ISO 9001 |

| Packeage | Box /Carton/Wooden Box/Plastic Tube or Per buyers requirement |

| MOQ | Depending On Moedl |

| Serice | OEM |

| Sample | Available |

| Payment | TT or L/C or Western Union |

| Port | HangZhou |

company information

Our Advantages

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to Southeast Asia(15.00%),Mid East(15.00%),North America(10.00%),Africa(10.00%),Eastern Asia(10.00%),Domestic Market(10.00%),South America(5.00%),Eastern Europe(5.00%),Oceania(5.00%),Central America(5.00%),South Asia(5.00%),Northern Europe(3.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing,Bearing parts,Mechanical parts,Auto parts,Bearing manufacturing

4. why should you buy from us not from other suppliers?

General items: bearing sales; Sales of high-speed precision heavy-duty bearings; Sales of high-speed and precision gear transmission devices; Bearings and drives are not available for sale; Bearing manufacturing

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

customers earn more money.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| The Number of Rows: | Single |

|---|---|

| Material: | Bearing Steel |

| Certification: | ISO 9001:2008 |

| Payment: | T/T,L/C at Sight Paypal Western Union |