Product Description

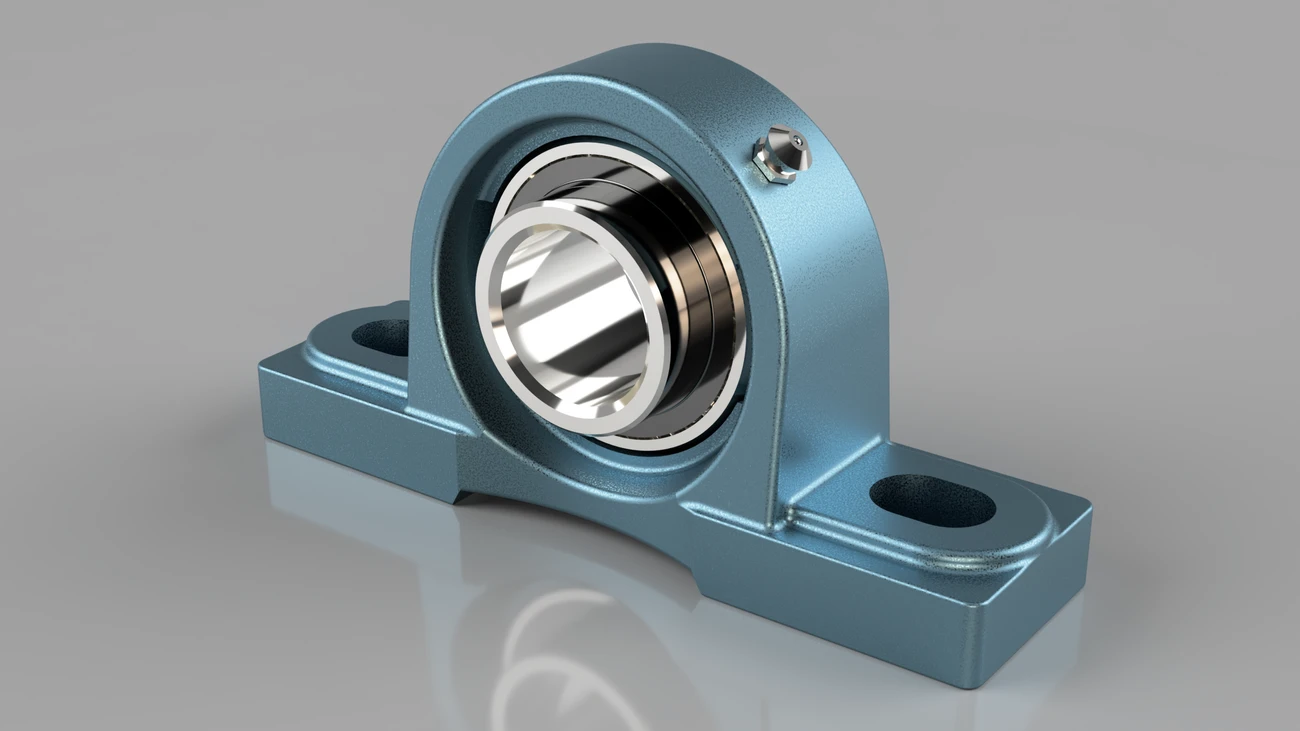

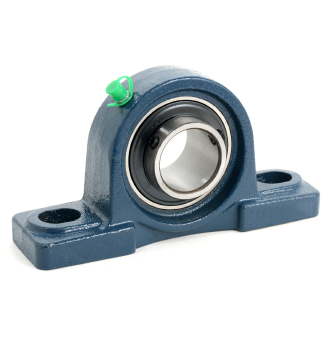

Agricultural Industry Machinery Harvest Reaping Wheat Corn Machine Pillow Block Bearing

Product Description

|

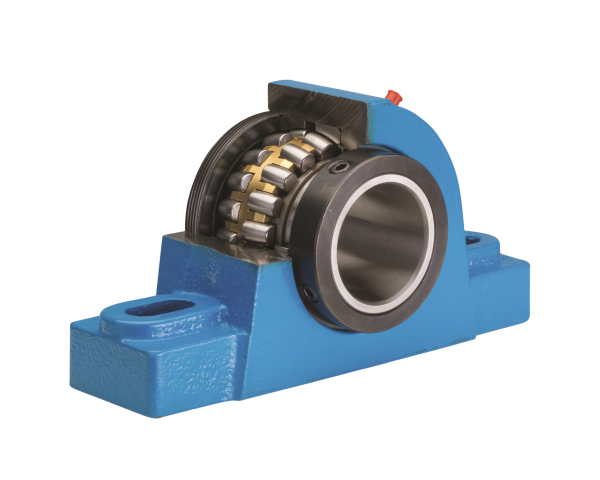

Pillow Block Bearing Pillow block ball bearing is actually a variation of the deep groove ball bearing, which outer diameter is spherical surface, can match into the corresponding concave spherical bearing self-aligning effct, bearings are mainly used to bearing radial direction load primarily radial and axial loads, and should not be commonly alone bear axial load,the bearing can be installed separately inner ring (with full set of roller and retainer) and outer ring. Pillow block ball bearing is suitable for the required equipment and parts of simple situation, such as used for agricultural machinery, transporation systems or on construction machinery. |

Product Parameters

Detailed Photos

Application

Company Profile

HangZhou HONGSHI MACHINERY AND ELECTRICAL EQUIPMENT CO.,LTD. (formerly HangZhou Hengmai Bearing Co., Ltd.) was established in 2007, and HMMH is our own brand.

HMMH mainly produces spherical roller bearings, pillow block ball bearing, deep groove ball bearings and cylindrical roller bearings. Spherical roller bearing products range from 20mm to 1M, with the main production of crusher bearings 22300 series. Low noise deep groove ball bearings, product accuracy can reach ZV2, ZV3, ZV4, mainly produces motor bearings 6200, 6300 series. pillow block ball bearing, mainly producing UCP, UCF, UCFL, UCFC, UCT series, the products are mainly used in agricultural machine and peeling machine. We also use the bainite quenching process to ensure the hardness of the bearing, using good testing equipment, such as roundness meter, profiler, roughness meter, universal measuring instrument, spectrometer, metallographic microscope to control each detail quality monitoring.

To ensure product quality, we have established a strict quality control system and an experienced team of engineers and after-sales service. From forgings to final products we have a strict quality control system.

Your needs are our production motivation, and your satisfaction is our goal. We are willing to serve our customers with the goal of “Quality First, Service First, Credit First”.

FAQ

1.A:How can I do customized design?

Q:We are request for the drawing with the measurement, material and other speicifcation as details as you can, and for the customized products, our MOQ is 10 pcs per design

2.Q: How can I get a sample?

A: If you only need 1or 2 samples for small size inner weight below 2kgs, we can supply free samples and we have stocks, you can just pay the shipping cost .if you need several design samples, then you should paid the cost with shipping.

3.Q: What package do you usually use?

A: Usually we use single box or tape. Also according to customer’s special requirement.

4.Q:How long do you need for production? Or what’s your production lead time?

A:Usually could be sent our in 2-3 days if in stock for samples. Customized item usually need 14-30 days to produce.

5.Q:How long will you guarantee your quality?

A:We supply test report and quality control photos from materials to finished goods during production.

6.Q:How to do after sale service?

A:Good after-sale service is our promise. Before placing orders, our professional engineer will discuss all technical data and your bearing usage condition and CZPT you what kind of steel materials to fit your products and usage life possible.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Separated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Product Name: | Pillow Block Bearing |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do pillow block bearings contribute to the proper functioning of food processing equipment?

Pillow block bearings play a crucial role in ensuring the proper functioning of food processing equipment. They provide reliable support and smooth operation for rotating shafts and components in various stages of food processing. Here are the key contributions of pillow block bearings to the proper functioning of food processing equipment:

- Sanitary Design:

- Reliable Performance:

- Corrosion Resistance:

- Contamination Prevention:

- Easy Maintenance:

- Versatility:

In food processing environments, maintaining strict hygiene standards is essential. Pillow block bearings designed for food processing equipment are constructed with materials and features that adhere to sanitary requirements. They are often made from stainless steel or other corrosion-resistant materials that are easy to clean and withstand frequent washdowns. Additionally, these bearings have smooth surfaces, rounded edges, and minimal crevices to prevent the accumulation of food particles, debris, or bacteria. The sanitary design of pillow block bearings ensures the integrity and cleanliness of the equipment, minimizing the risk of contamination and ensuring compliance with food safety regulations.

Food processing equipment operates under demanding conditions, including high production rates, heavy loads, and frequent start-stop cycles. Pillow block bearings are designed to withstand these challenges and provide reliable performance. They offer excellent load-bearing capacity, shock resistance, and vibration damping capabilities. This ensures smooth and stable operation of rotating shafts, reducing the risk of equipment failure, downtime, and production interruptions. By contributing to the reliable performance of food processing equipment, pillow block bearings support efficient and uninterrupted food processing operations.

Food processing environments often involve exposure to moisture, chemicals, and cleaning agents. Pillow block bearings designed for food processing equipment are highly resistant to corrosion and chemical attack. They are made from materials that can withstand the corrosive effects of food acids, cleaning solutions, and other substances encountered in the processing area. The corrosion resistance of these bearings helps maintain their structural integrity, extends their lifespan, and ensures reliable performance even in harsh operating conditions.

Preventing contamination is of utmost importance in food processing. Pillow block bearings incorporate sealing mechanisms, such as rubber seals or labyrinth seals, to prevent the entry of contaminants into the bearing housing. These seals provide a barrier against dirt, dust, moisture, and other external elements, minimizing the risk of contamination of the food products. The effective sealing of pillow block bearings helps maintain the cleanliness and purity of the processing environment, safeguarding the quality and safety of the food products.

Maintenance and cleanliness are critical in food processing equipment. Pillow block bearings are designed for easy maintenance, inspection, and cleaning. They often have features such as grease fittings or lubrication access points that facilitate the replenishment of lubricants without disassembling the bearing. This simplifies routine maintenance tasks and allows for timely lubrication, ensuring optimal bearing performance. The ease of maintenance of pillow block bearings contributes to the overall efficiency and reliability of food processing equipment.

Food processing equipment encompasses a wide range of applications, such as mixing, grinding, conveying, and packaging. Pillow block bearings offer versatility and can be used in various equipment types and configurations. They are available in different sizes, load capacities, and mounting options to accommodate the specific requirements of different food processing applications. The versatility of pillow block bearings allows for their integration into diverse equipment designs, supporting the proper functioning of food processing machinery.

In summary, pillow block bearings contribute to the proper functioning of food processing equipment by offering a sanitary design, ensuring reliable performance, providing corrosion resistance, preventing contamination, enabling easy maintenance, and offering versatility. By fulfilling these roles, pillow block bearings support the efficient, hygienic, and uninterrupted operation of food processing equipment while maintaining the highest standards of food safety and quality.

How do pillow block bearings enhance the performance of agricultural machinery like tractors?

Pillow block bearings play a vital role in enhancing the performance of agricultural machinery, including tractors. Their contributions to the functionality and efficiency of tractors can be outlined as follows:

- Support and Load Handling:

- Reduced Friction and Wear:

- Alignment and Stability:

- Contamination Protection:

- Maintenance and Accessibility:

Pillow block bearings provide essential support for the rotating shafts and other moving components in agricultural machinery, such as tractors. They handle and transmit the loads applied to the machinery, including the weight of the equipment, implements, and the forces encountered during operation. By effectively supporting the shafts and components, pillow block bearings help maintain the structural integrity of the machinery and ensure smooth and efficient movement, contributing to overall performance.

Pillow block bearings are designed to minimize friction between the rotating shafts and the bearing housing, reducing energy losses and wear. By incorporating rolling elements, such as balls or rollers, pillow block bearings facilitate smooth motion with reduced friction. This friction reduction results in improved energy efficiency, reduced power consumption, and extended lifespan of the bearings and other related components in the agricultural machinery like tractors.

Proper alignment of the components is crucial for the efficient operation of agricultural machinery, including tractors. Pillow block bearings aid in aligning and supporting the shafts and other moving parts, ensuring they remain centered and in the correct position. This alignment helps prevent excessive vibrations, reduces the risk of misalignment-related issues, and promotes stable and consistent performance, enhancing the overall functionality of tractors.

Agricultural environments can be harsh, with exposure to dust, dirt, moisture, and other contaminants. Pillow block bearings are designed to provide protection against these contaminants. They often incorporate sealing mechanisms, such as rubber seals or labyrinth seals, to prevent the entry of foreign particles into the bearing. This protection helps maintain the cleanliness of the bearing’s internal components, reducing the risk of premature wear, corrosion, or damage, and contributing to the reliable and efficient operation of tractors.

Maintenance is an essential aspect of ensuring the performance and longevity of agricultural machinery like tractors. Pillow block bearings are designed with ease of maintenance in mind. They often feature a split housing design that allows for convenient access to the bearing without the need to disassemble the entire machinery. This accessibility simplifies maintenance tasks, reduces downtime, and promotes efficient upkeep of the bearings, contributing to the overall performance and reliability of tractors.

In summary, pillow block bearings enhance the performance of agricultural machinery like tractors by providing support, handling loads, reducing friction and wear, ensuring alignment and stability, protecting against contaminants, and offering ease of maintenance. With their crucial role in supporting and facilitating the movement of shafts and components, pillow block bearings optimize the performance, energy efficiency, and lifespan of agricultural machinery, contributing to improved productivity and reliability in farming operations.

What are pillow block bearings and how are they used in various industrial applications?

Pillow block bearings, also known as plummer block bearings, are a type of bearing mounted inside a housing or block, typically made of cast iron or pressed steel. These bearings are widely used in various industrial applications due to their versatility and ease of installation. Here’s a detailed explanation of pillow block bearings and their uses:

- Design and Construction:

- Supporting Shaft Loads:

- Easy Installation and Maintenance:

- Versatility and Adaptability:

- Environmental Protection:

- Specialized Variations:

A pillow block bearing consists of a bearing insert (such as a deep groove ball bearing, spherical roller bearing, or cylindrical roller bearing) and a housing or block. The housing is typically a split design that allows for easy installation and maintenance. It usually has a flat base with mounting holes for attachment to a support structure, such as a machine frame or conveyor system. The bearing insert is pre-mounted inside the housing and provides the rotating element to support shafts or other moving parts.

Pillow block bearings are primarily used to support rotating shafts and transmit loads between the shaft and the housing. They are capable of handling both radial and axial loads, depending on the type of bearing insert used. The design of the pillow block bearing allows for self-aligning capability, which helps accommodate slight misalignments or shaft deflections, ensuring smooth operation and reducing stress on the bearing.

One of the key advantages of pillow block bearings is their ease of installation and maintenance. The split housing design allows for quick assembly and disassembly without the need to remove other components or disassemble the entire system. This feature simplifies bearing replacement, lubrication, and inspection, reducing downtime and maintenance costs in industrial applications.

Pillow block bearings are highly versatile and adaptable to various industrial applications. They can be found in a wide range of industries, including manufacturing, mining, agriculture, construction, and material handling. These bearings are used in conveyor systems, power transmission equipment, pumps, fans, compressors, and many other rotating machinery applications.

Pillow block bearings are designed to provide a degree of environmental protection to the bearing insert. The housing acts as a shield, preventing contaminants such as dust, dirt, and moisture from entering the bearing and causing premature failure. Additionally, the housing design often includes provisions for grease or oil lubrication, further protecting the bearing and ensuring proper lubrication for optimal performance.

While the basic design of pillow block bearings remains the same, there are specialized variations available to meet specific application requirements. These include corrosion-resistant bearings for harsh environments, high-temperature bearings for elevated temperature applications, and sealed bearings for applications where additional protection against contamination is needed.

In summary, pillow block bearings are bearing units housed in a block or housing, widely used in various industrial applications. They provide support for rotating shafts, transmit loads, accommodate misalignments, and offer easy installation and maintenance. Their versatility, adaptability, and environmental protection make them suitable for diverse industrial sectors. With specialized variations available, pillow block bearings can be customized to meet specific application needs, ensuring reliable and efficient operation in a wide range of industrial machinery and equipment.

editor by CX 2024-04-29